A recall is the worst-case scenario for any company. It leads to enormous costs and makes for negative headlines. Recalls are by no means uncommon. According to statistics, there are approximately 300 product recalls in Germany alone and over 2,000 Rapex notifications from the European member states each year. The costs resulting from rework can quickly run into tens of millions of dollars. Reducing these scenarios by just 1% can save an enormous amount of money.

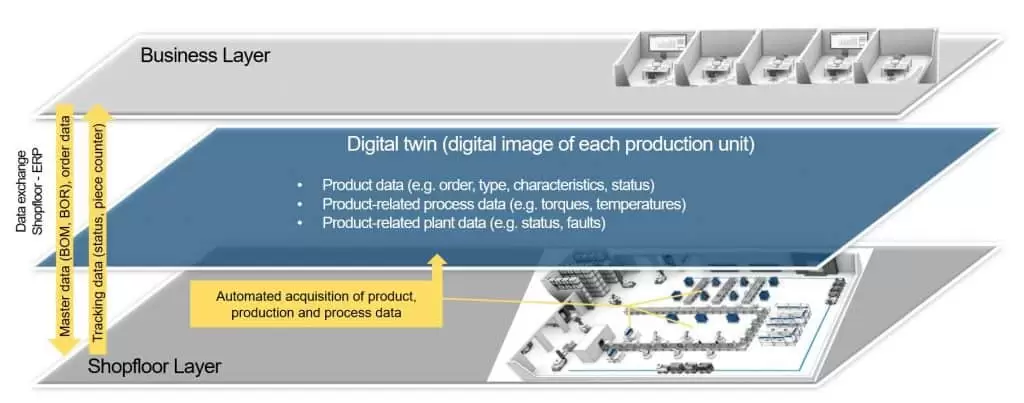

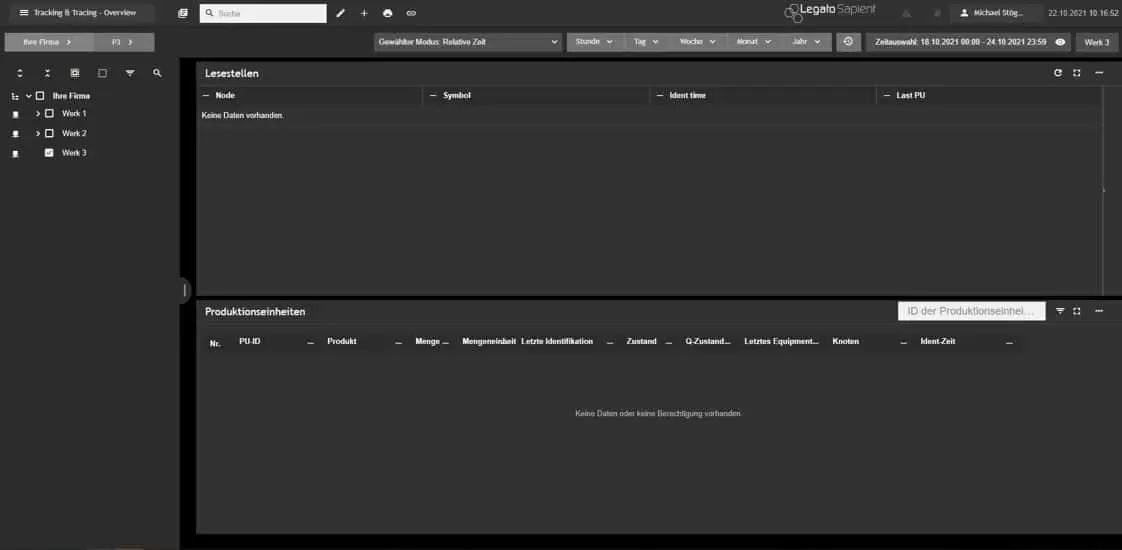

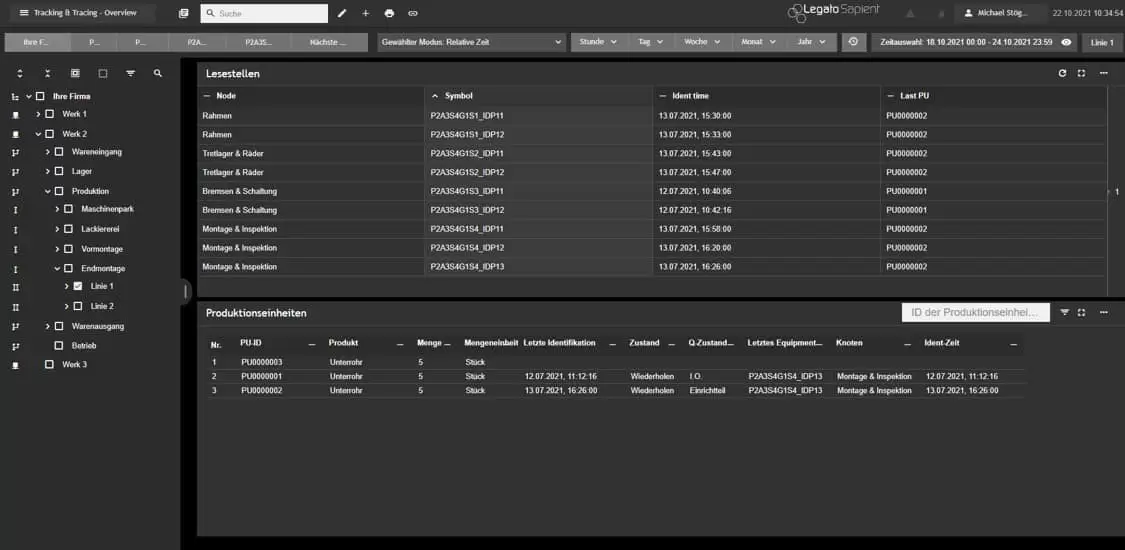

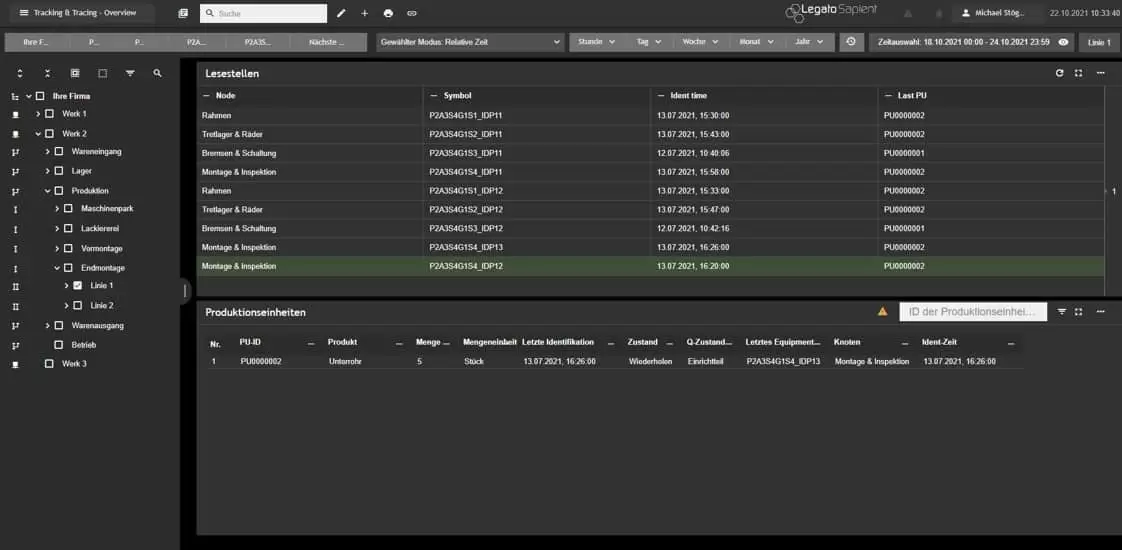

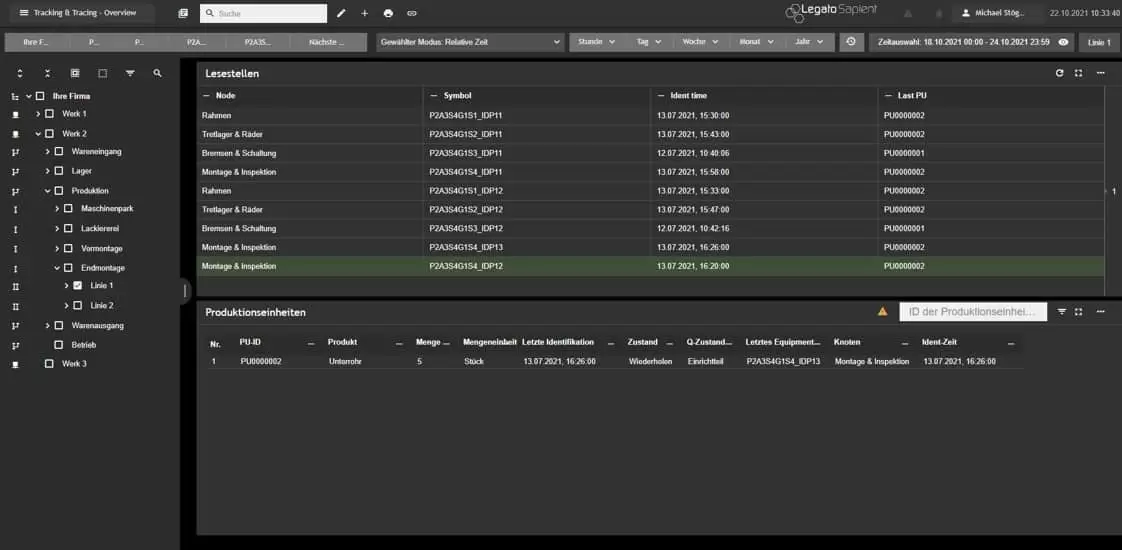

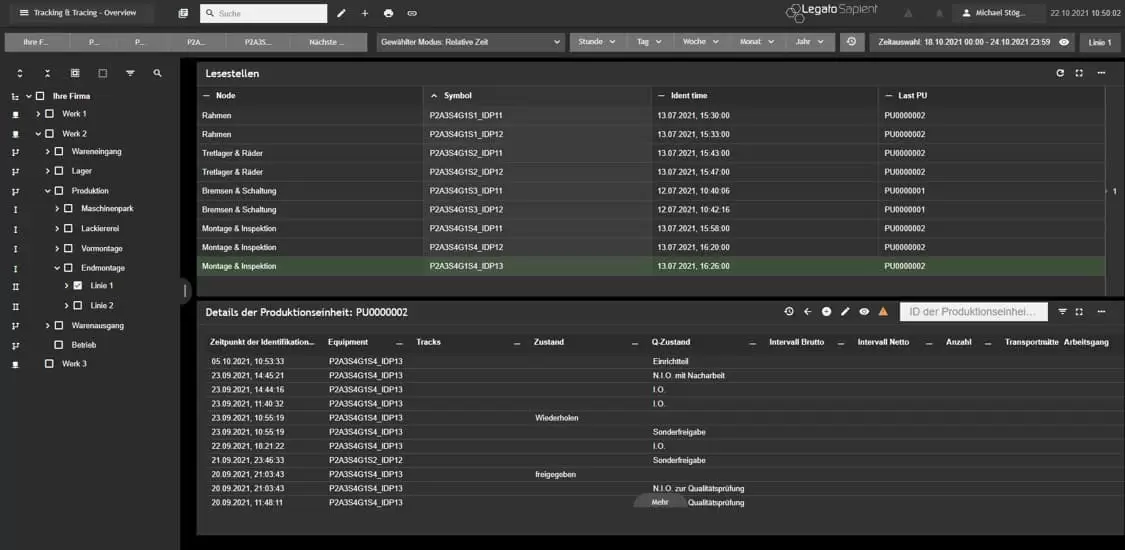

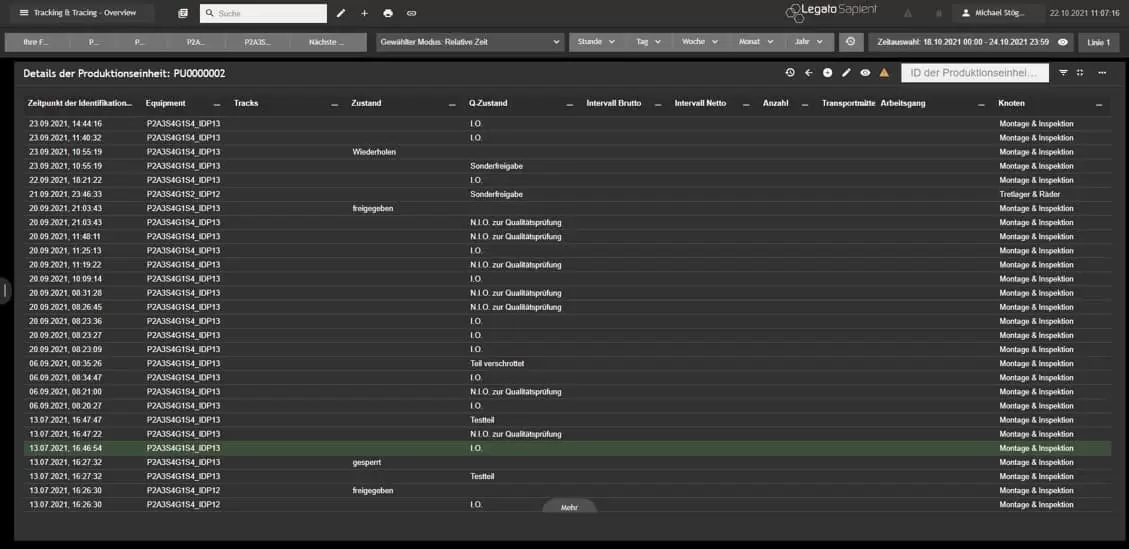

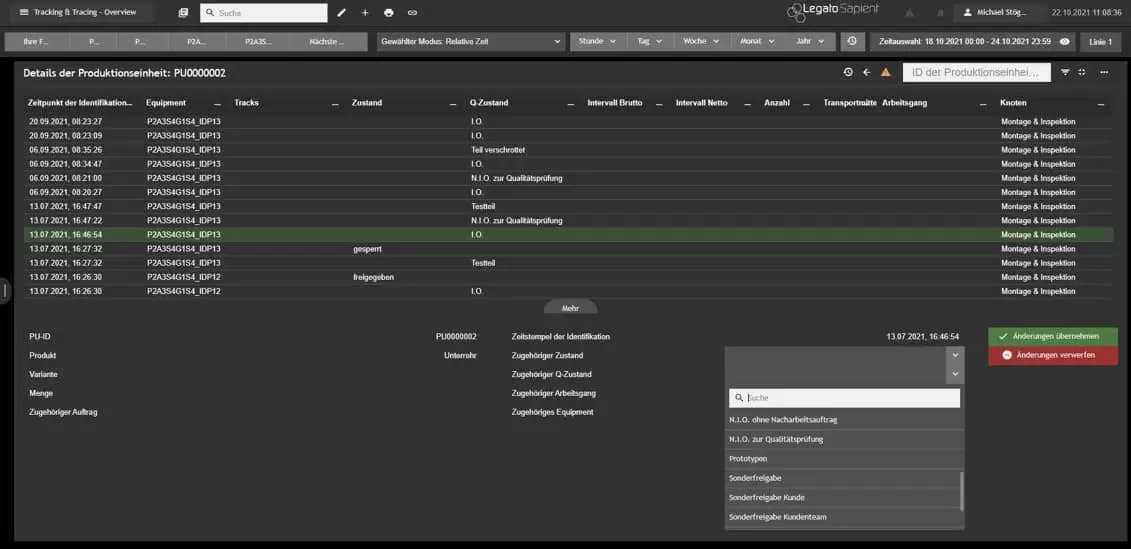

The best way to avoid them is to identify quality problems in production at an early stage and take immediate action. If a recall is necessary in spite of everything, it must be fast and targeted. Automated track and trace solutions are needed to ensure quality standards and continuous improvement of production processes, as well as to facilitate product and part track and trace.

Advantages of traceability MES software:

- traceability in production

- transparency from the raw part through the production process of the individual parts to the end product

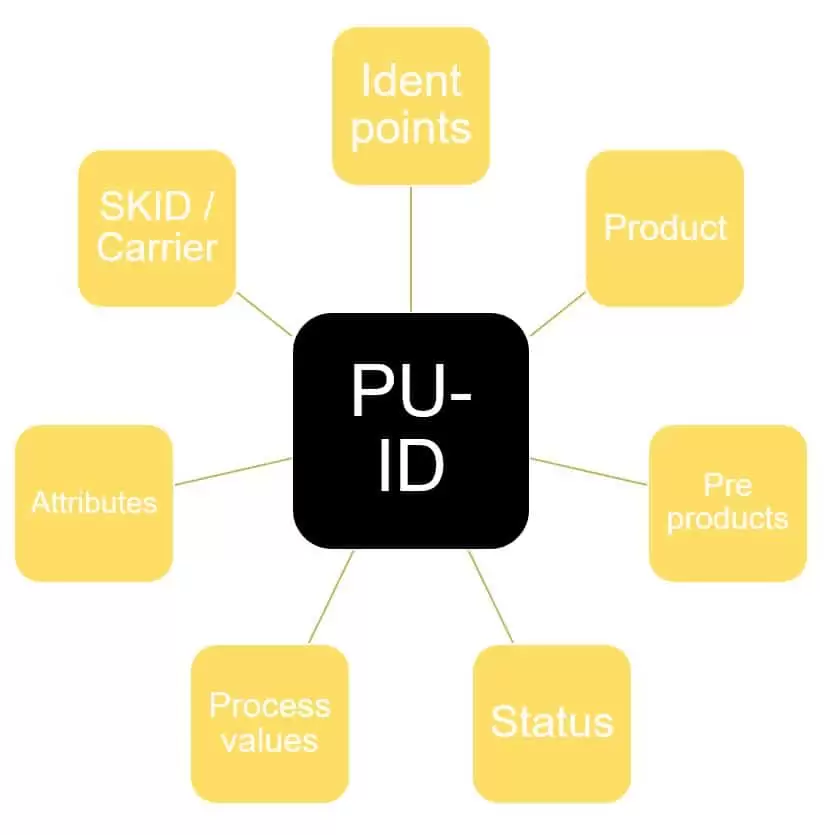

- linking of production orders with unique serial numbers of the individual parts (track & trace labels, barcodes, FINs, lot, serial and batch numbers, data matrix codes or an RFID chip)

- assignment of almost any data record to a product through track and trace

We are happy to show you the advantages of our MES software Legato Sapient in a personal meeting and answer your questions in detail.