Machine downtimes or even standstills are the worst-case scenario in manufacturing. It is therefore obvious that maintenance is one of the elementary adjusting screws for making production more efficient and reducing costs.

Equipment and machine monitoring brings you the following benefits:

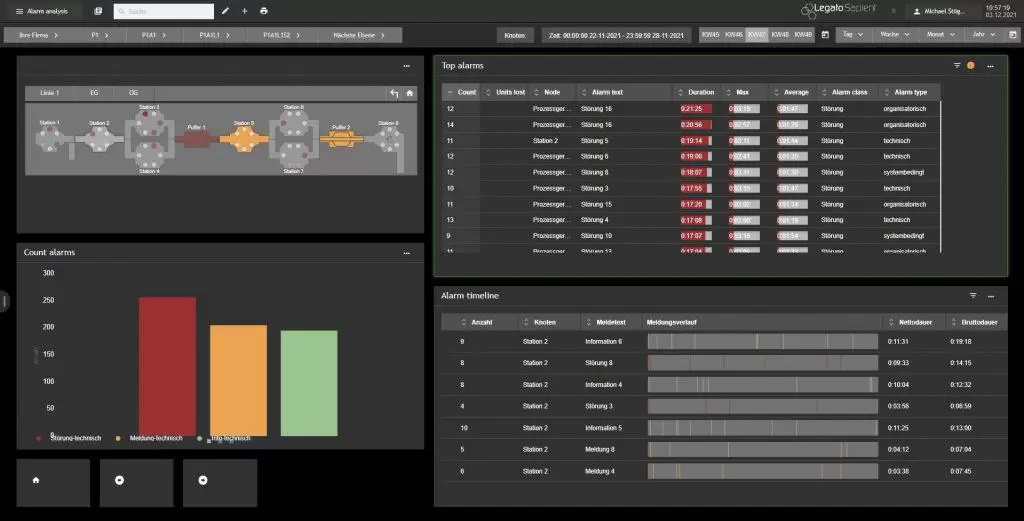

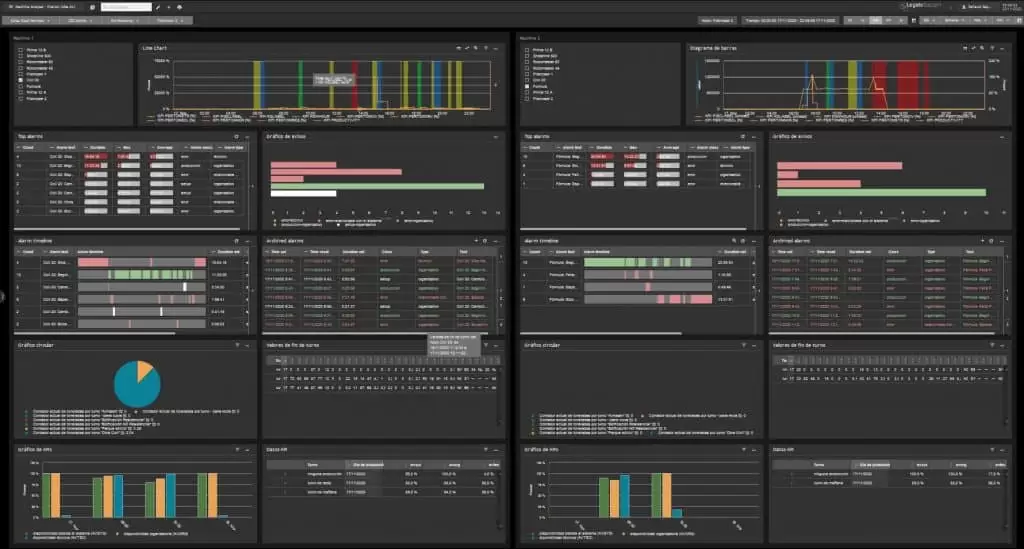

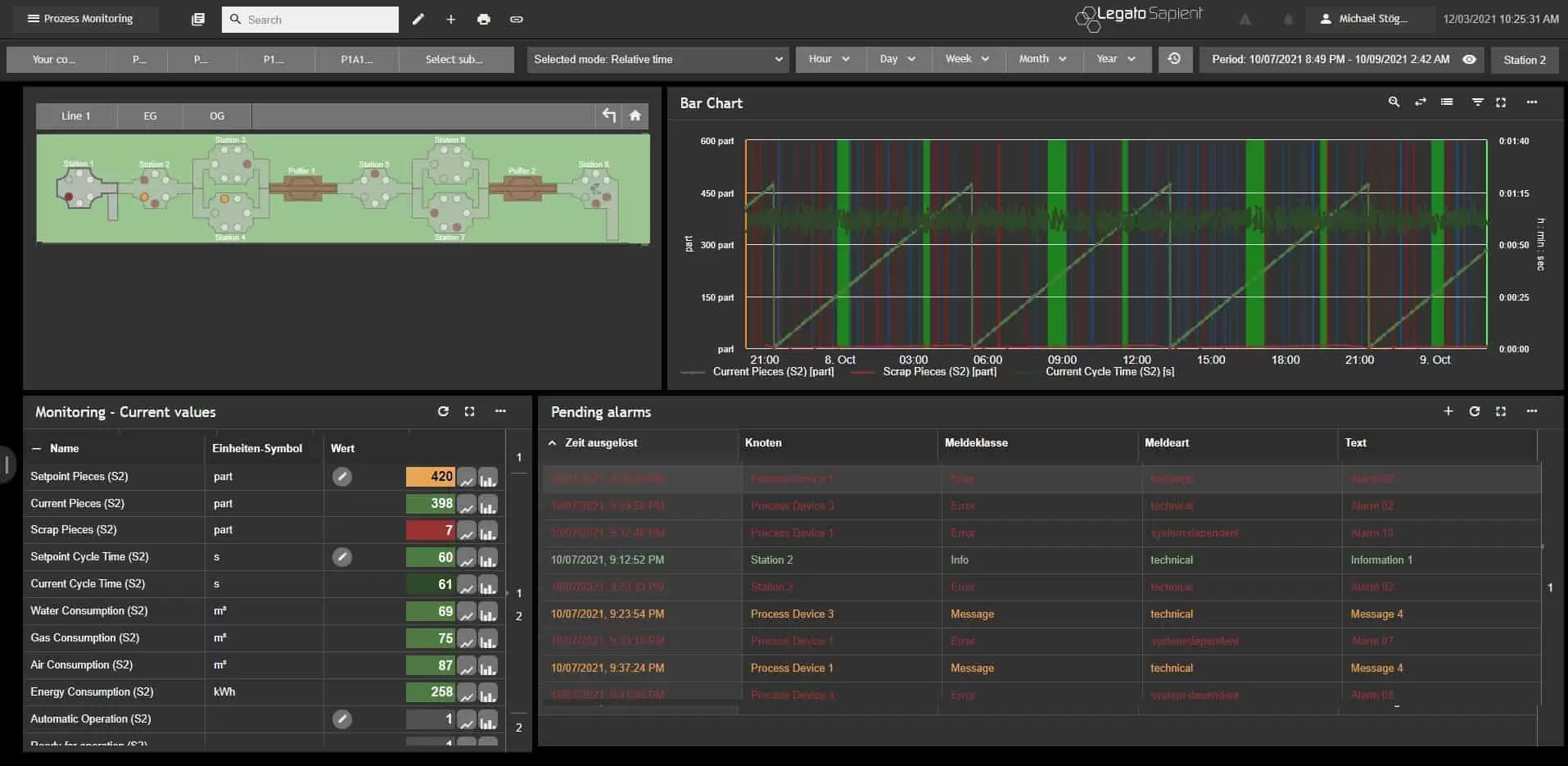

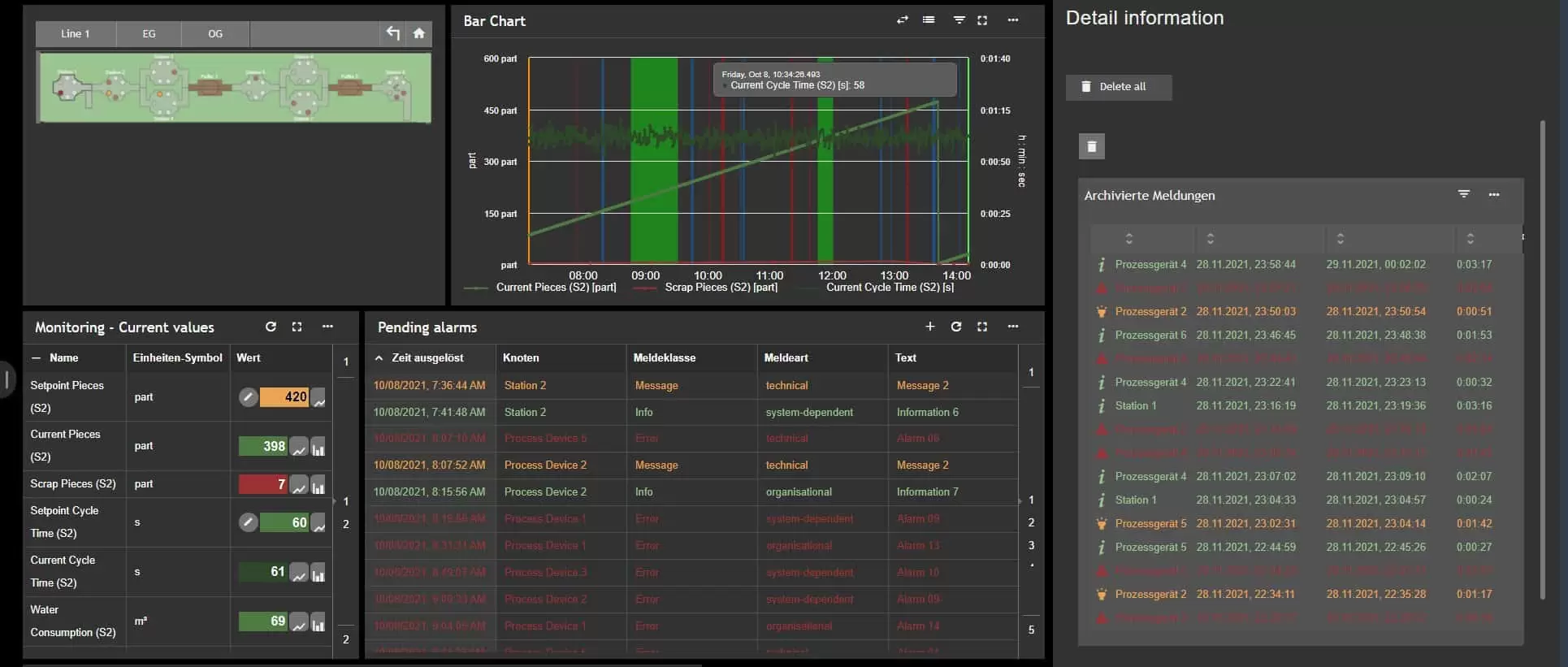

- Greater transparency by machine monitoring throughout the entire manufacturing process

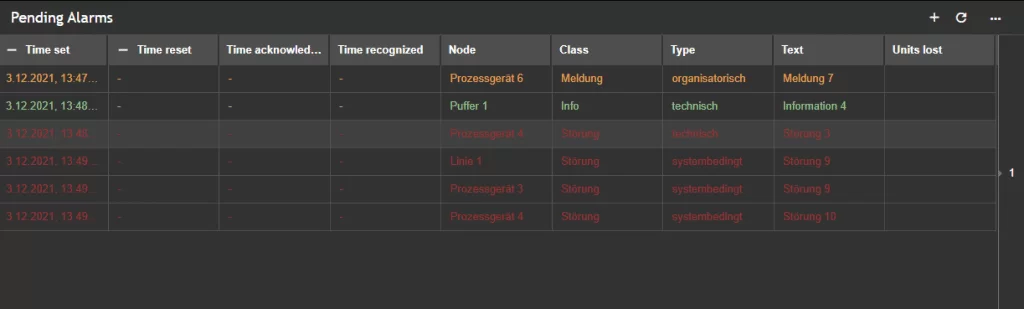

- Faster detection of plant downtimes

- Automatic notification system in case of downtime

- Reduction of machine and plant downtimes

- Increased output due to increased equipment availability

We would be pleased to show you the advantages of our MES software solution Legato Sapient in a personal appointment and to answer your questions in detail.