These companies are handpicked for their skills, experience and ability to meet the needs of their customers. Gefasoft and our partners work together, from system integration to the deployment of new features. Find out more about the companies GEFASOFT works with:

- Business partnerships in IIoT

- Huawei’s Smart Factory in Munich/Ismaning

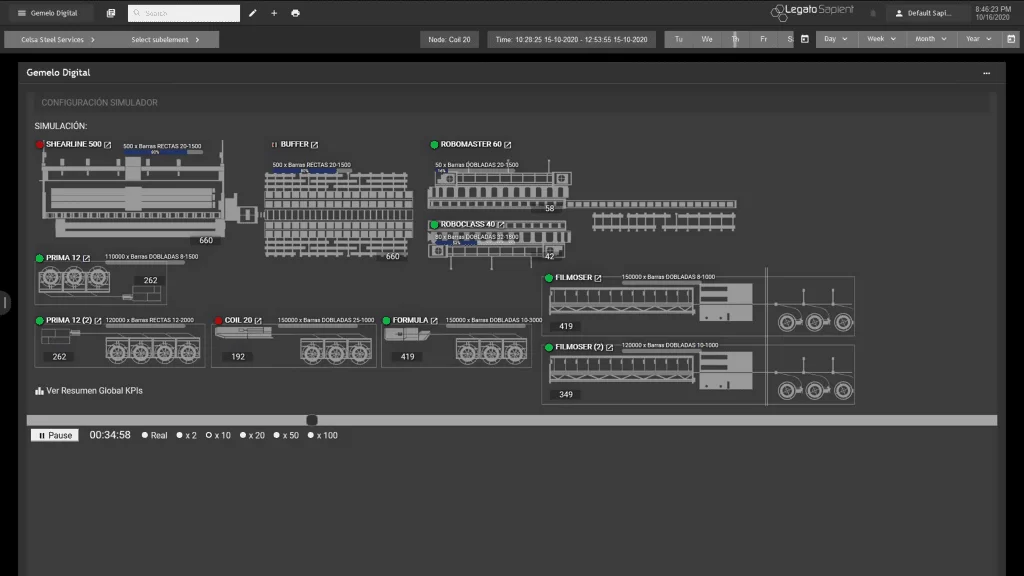

- European project IoT4Digitaltwin with Geprom, Gefasoft and Celsa

- Industry Business Network 4.0 & IndustryFusion Project

Business partnerships in IIoT

Neglecting collaboration in IIoT means decelerating progress. Therefore, it is one of GEFASOFT’s declared goals to establish and maintain business partnerships. This is to enable medium-sized as well as large corporate companies to take part in the digital transformation and become a Smart Factory – on the one hand through scalable solutions, on the other hand through open source MES systems. That way, GEFASOFT contributes to an economical and sustainable manufacturing industry.