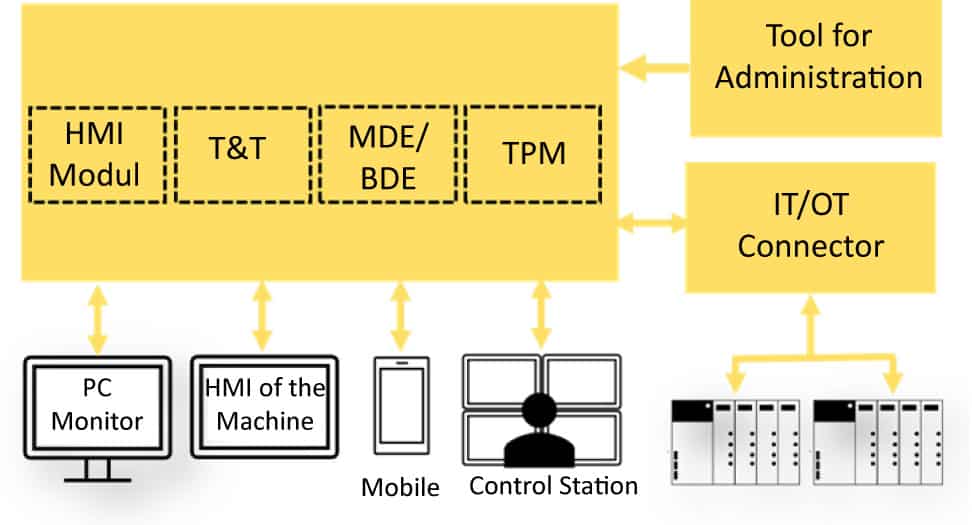

Do you shy away from linking the control level and the shop floor for fear of network and associated system failures? Do you forego the opportunity to have a consistent view of production data because of the feared effort? With the help of the web-based HMI module, Legato Sapient combines the decentralized view of the machine with the overall view in the shopfloor level. This way, you not only have all the information in one central system, but also reduce your costs for hardware and middleware.

Fail-safe network as a production-critical medium

For a long time, line systems for compressed air, water and electricity were the supporting components in the supply backbone of production halls. With the triumph of digitization, another medium has now been added: the network for transmitting digital data. Not only people, but also machines, assets and systems can communicate with each other via this network – so in today’s world, a network failure is equivalent to a power outage, and both are prevented as best as possible. A move away from the classic, cost-intensive FAT clients is thus possible.

Reduce costs for hardware, middleware and operation

Legato Sapient’s web-based HMI module runs as a browser application and only requires a thin client to communicate with the central server. Complex calculations therefore do not have to be performed on site, as was previously the case, but are made available centrally. This conserves resources and enables the use of significantly less expensive hardware and middleware at the terminals.

Another advantage of this central provision of data lies in maintenance. Instead of updating each terminal in the entire production area individually when changes are made, this can be done centrally and quickly via the server, e.g. when versions are changed or the visualization library is updated. Similarly, backups of data no longer have to be created on site at the machines, but can be centrally administered, monitored and controlled. In the event of a hardware replacement, all that needs to be done is to open a current web browser and the HMI interface can be used again.

In addition, our combined solution of the MES Legato Sapient and our new HMI module offers a uniform operating concept. The result: a homogeneous system landscape including uniform maintenance contracts and a low number of key users leads to lower costs for hardware/middleware and in operation.

Performance of our HMI module

The web-based HMI module is compatible with machines from different suppliers and also supports large machine parks with several hundred individual stations. Each terminal is assigned a unique ID in the system, and a rights concept regulates user-specific functions for monitoring and controlling the machines. This ensures, for example, that critical control functions can only be executed within the visual range of the machine so as not to endanger the safety of personnel.

For time-critical controls, latency times of less than one second are a matter of course. To ensure this, the data for defined commands does not flow via the database, but without detours to the machine control. This happens, for example, when a spindle is stopped manually before a faulty component causes damage to the system.

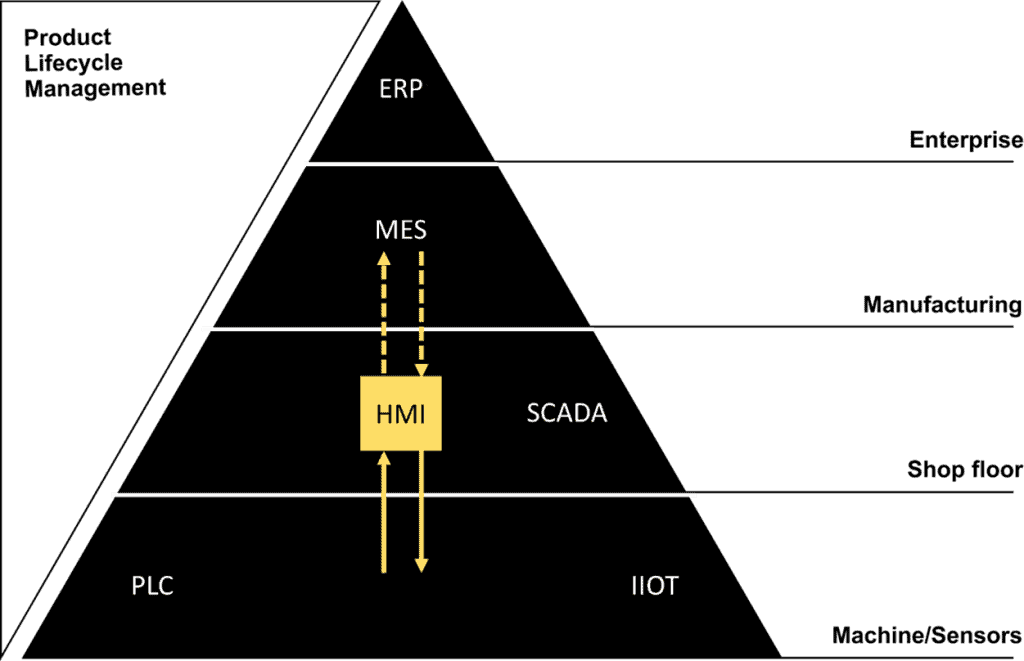

Transparent view across all levels

The integration of a web-based HMI into the Legato Sapient control system creates many advantages: By integrating control station displays into local operator interfaces, operators gain unprecedented transparency for the entire manufacturing process. Here, the operator view can be accessed from anywhere, and the whole overview of the shopfloor is also visible to the operator. Fast and flexible switching between different visualizations in both levels is possible.

The web-based HMI module provides a transparent view of the production data across all levels – in real time and without any system interruption. This creates a central system for all control functions and information required for uninterrupted operation. When irregularities occur, the centrally available data helps speed up the decision-making process.

Your machine operator on site can also keep an eye on the big picture with the HMI module. In addition to information from his “own” machine, he also has access to relevant data from other dashboards and HMIs. For example, he can quickly see where the fault lies if the machine has to be stopped, e.g. due to a lack of parts. Thanks to the uniform database and the location-independent views, visualizations only have to be created once and can be used in both the HMI and the MES.

Uniform creation through the HMI Designer

Those who create new visualizations or edit existing ones use our HMI Designer. This offers a central library function that contains standard libraries for graphical elements, as well as associated “data connections”. This reduces the effort and automatically ensures standardization of the HMI visualizations.

Although the library already includes a large number of elements (e.g. process engineering symbols DIN EN ISO 10628), you can easily extend it if required. In addition, it is possible to link elements with production data in the HMI Designer. Due to the low-code approach, even users without programming knowledge are able to integrate formulas and resulting dynamizations directly into the visualizations.

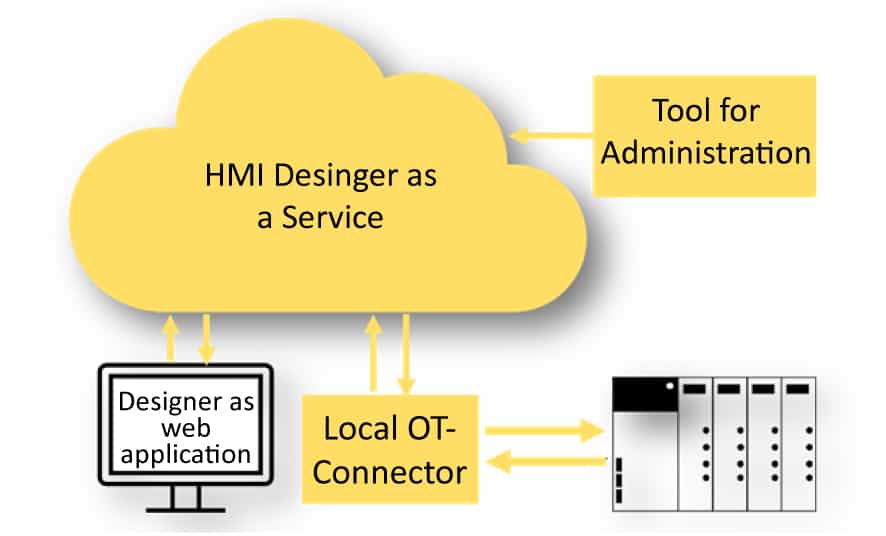

Virtual pre-commissioning at the plant supplier

HMI visualizations are typically created by machine suppliers and are part of the scope of delivery of new machines. Here, too, machine and asset suppliers can benefit from our HMI concept, because we offer the HMI Designer as an as-a-service solution.

The respective supplier is provided with an environment in the cloud incl. live connection of his machine. In this way, the HMI projects can already be prepared and tested at the supplier’s site and then transferred remotely to the customer’s system. This is our contribution to accelerated commissioning and roll-out of new machines.

Use Case:

Car manufacturer takes advantage of HMI module

A German car manufacturer took advantage of Legato Sapient including the integrated HMI module: a significant reduction in hardware and middleware costs thanks to the web-based concept; lower project planning costs thanks to the as-a-service approach and vendor independence. Where previously a consistent data and information basis was lacking due to system breaks between the manufacturing level (MES) and the shop floor (HMI), the vehicle manufacturer can now call up any HMI visualization on the central control system and on the HMI terminal of any machine. Because the views no longer have to be created twice, the company has been able to significantly reduce project planning costs – and thanks to the web-based solution, all of this is possible without expensive, high-maintenance hardware for HMI terminals.

If you would like to know more, visit our Legato Sapient website or fill out our contact form.

Downloads