1. IT/OT Integration for EdgeOne and other IT Systems

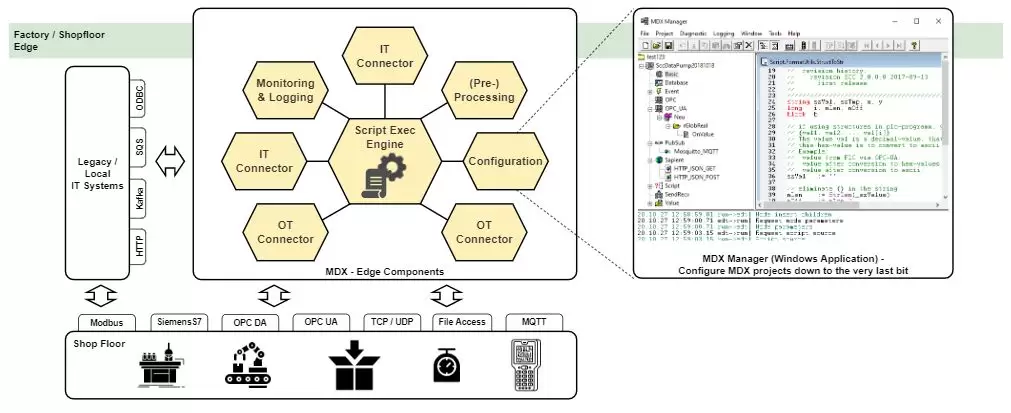

The “Machine Data eXchange (MDX)” product family is used in the context of industrial production to implement data exchange between machine controls (operational technology / OT devices) on the store floor and various IT systems (information technology). For this purpose, MDX offers several OT Connectors (OTC) on the Windows operating systems and various Linux distributions for connecting the OT devices and an IT Connector (ITC) for connecting IT systems.

2. Project-specific scripting on-the-edge with IT/OT integration

Project-specific scripts can also be executed within the IT Connector. This enables the preprocessing and enrichment of data with its context as well as the implementation of customer-specific business logic on the edge. In particular, scripts can also be used to dynamically create and terminate connections.

Thus, new machines and devices can be connected without the need to restart the connectors. For project planning, the MDX product family provides user programs under Windows. These programs enable the easy deployment of the connectors, their parameterization, and the creation of scripts for execution in the ITC.

Our IT/OT integration MDX

- offers a variety of possibilities for data (pre)processing (calculation, formatting, etc.)

- scripts are a flexible tool for program control

- independent script language, whose command set is adapted to special requirements

- Syntax is based on a standardized language (Structured Text from IEC1131)

- About 200 script commands are available for script programming

- The processing of the scripts is strictly event-driven

- Selectable timers, each change of a variable value or the reception of a telegram can be used as events

- For complex applications, the scripts can be structured in a clear form (“building block box”)

- Frequently used scripts in the context of Legato Sapient and EdgeOne are provided in a library

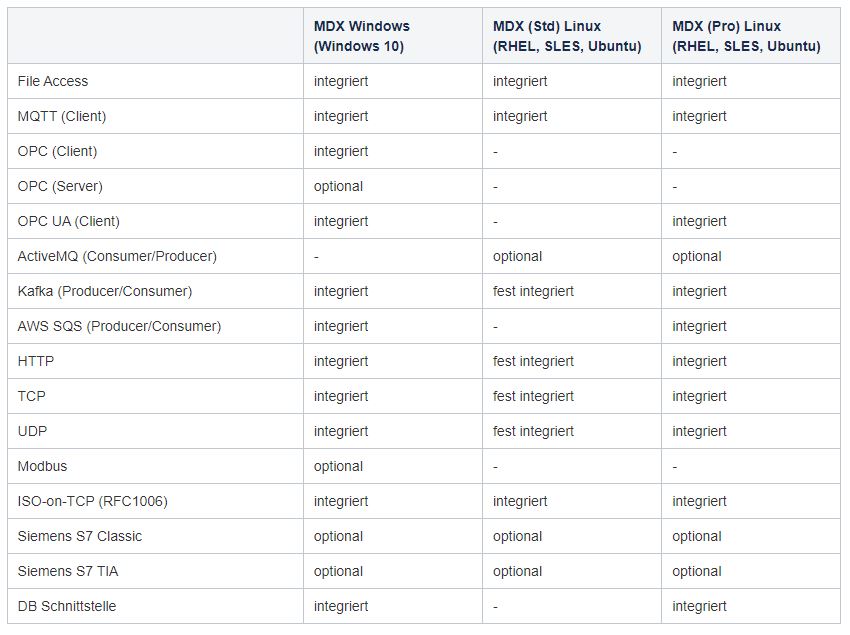

3. Available IT/OT interfaces in MDX

There are many standard device integrations delivered out of the box – whether for connecting different control types or for ERP/QMS/MES integrations. Furthermore, due to the division of the product into IT Connector and (several) different OT Connectors, any device integrations can be realized, also using 3rd party driver modules. The following table gives an overview of the available device integrations within the MDX product family.

Please contact us for a detailed description of the available interfaces.

4. Machine and production data acquisition in IT/OT integrations

When connecting production plants or process devices, any type of data with a wide variety of formats can be captured and processed by the MDX data gateway.

The type of data to be captured is secondary, i.e., it does not matter whether it is e.g., production data, order data, tool and fixture data or machine states.

Furthermore, manual acquisition, data entry (values, manual messages, message evaluation, etc.) can be carried out via the standard interfaces of the web client.