In the morning briefing in the classic sense, all employees are brought up to speed on the basis of overarching standards, topics from the previous day are discussed and the results from this conversation are discussed in front of a whiteboard. The morning briefing or shopfloor management usually includes topics from the areas of quality, occupational safety, productivity/performance, action control and logistics.

Digital Shopfloor Management

- Home

- Digital Shopfloor Management

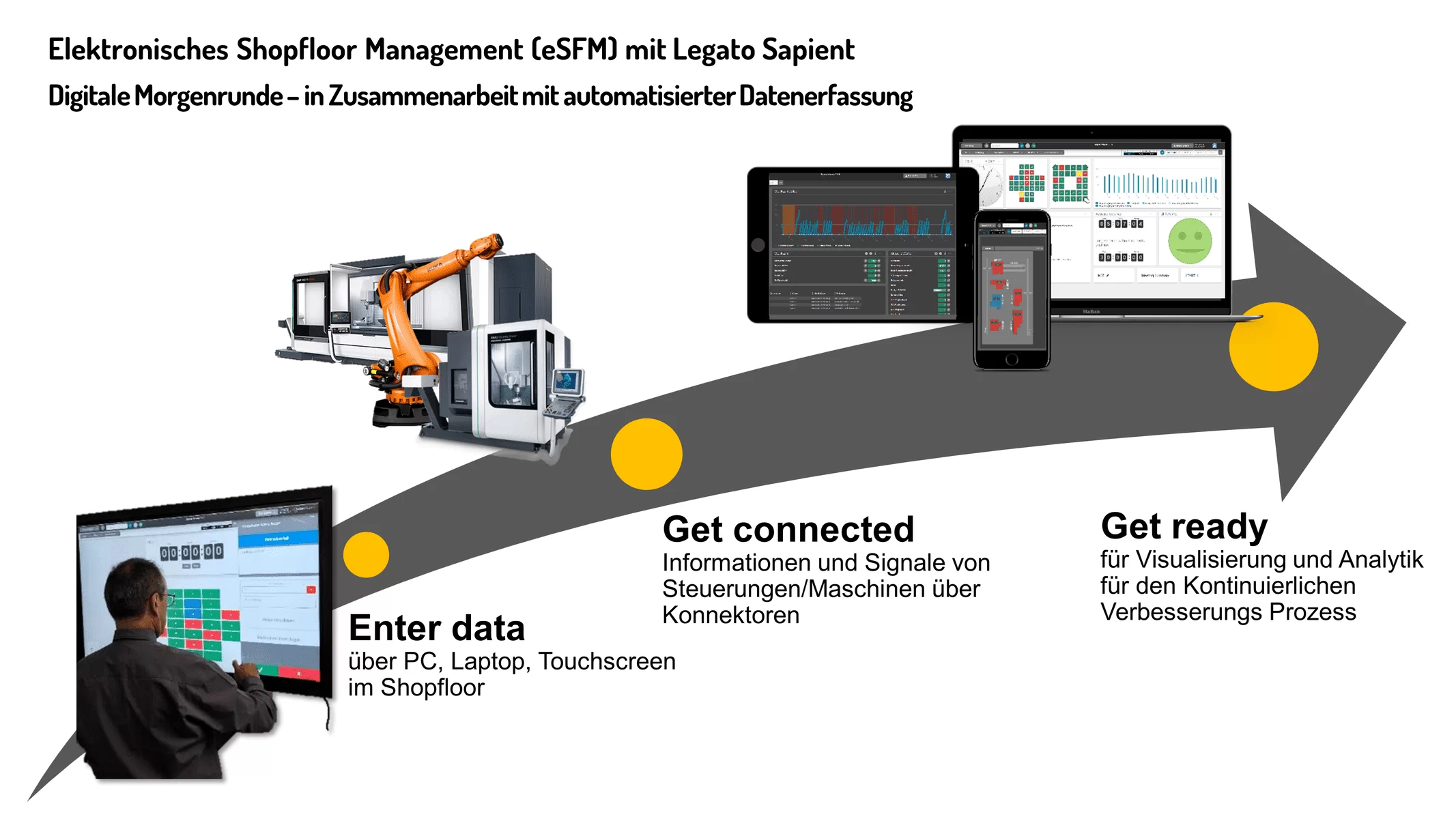

In many production companies, the morning briefing or shopfloor management has established itself as a highly effective tool for continuous improvement. Nevertheless, in the age of Industry 4.0 and digitalization (Digital Factory), new opportunities and possibilities arise as to how existing processes can be adapted and optimized, in line with the motto “Traditions have proven themselves… and still have to change”, while retaining the fundamental content of the classic morning briefing.

Digital shopfloor boards

The digitization of the morning briefing as digital shopfloor management replaces the previous decentralized preparation of data in tools such as Excel or Power-Point. Instead, a central system is used to collect data, archive it, make it available and prepare it. This digitization of the morning briefing brings with it a number of advantages, which are summarized here as examples in five efficiency fields:

1. Information transfer across shifts and departments

For the morning briefing in the classic sense, the manual effort required for preparation is often considerable, as the relevant data has to be compiled and prepared and then posted on the bulletin board in paper form. Despite the considerable effort required for preparation, the information is only available locally (morning briefing pinboard for paper-based information sharing).

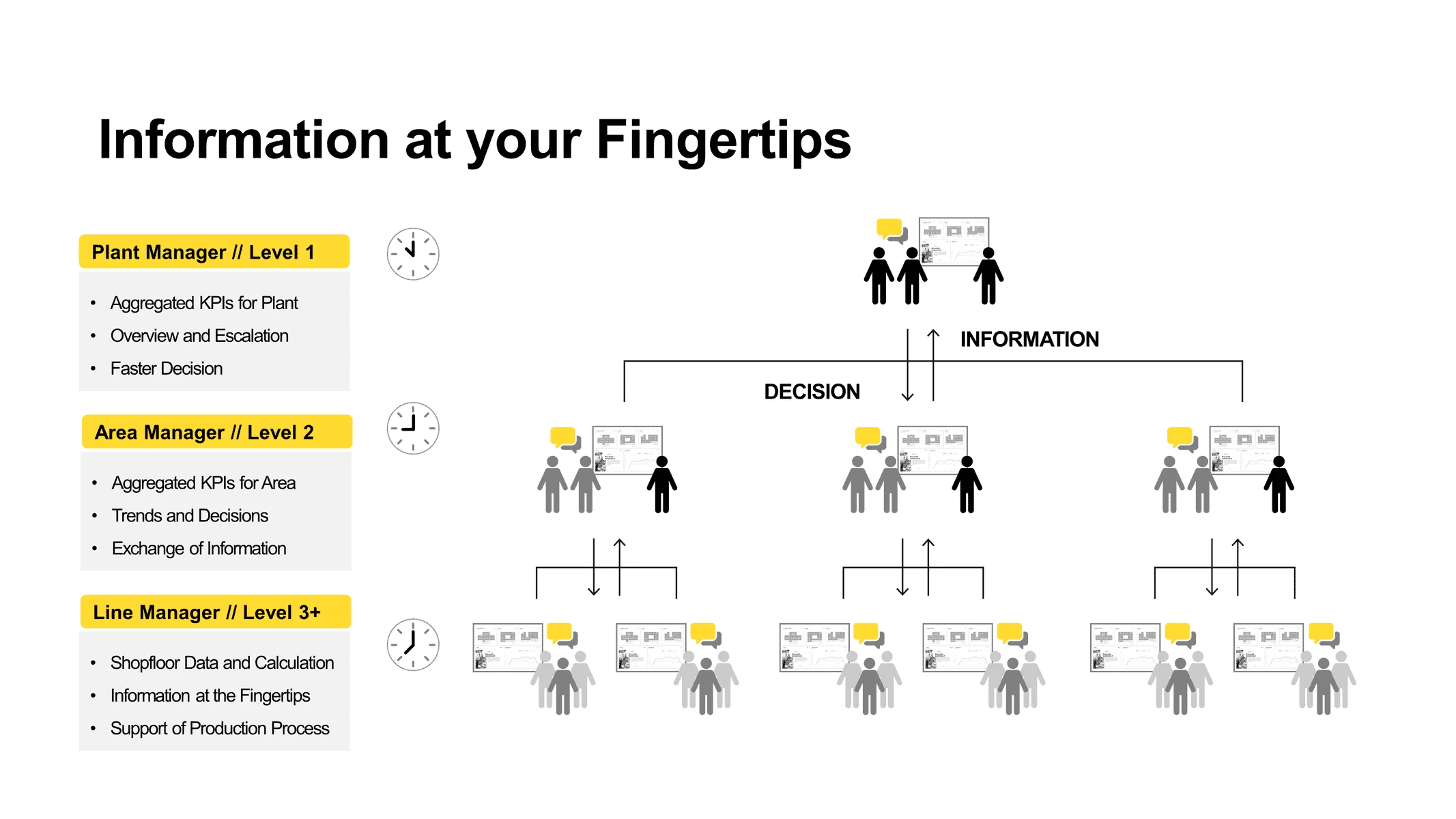

Through the use of a central, database-based system and the corresponding automated provision of the data, the information is available at all times and everywhere. This is the only way to ensure that essential information is distributed easily and quickly. If, for example, plant malfunctions or other problems occur, this information is not only important for the participants in the morning briefing; it should be distributed to other areas as easily and quickly as possible, to enable the shortest overall reaction time.

2. Flexible data analysis on demand

As already described, an enormous amount of preparation is required to prepare the data for the classic morning briefing (Excel, Power-Point, etc.) and make it available to the employees. If problems are identified, further information may be of importance that is not available or has to be prepared first.

Thanks to the electronic recording (automatic and manual) of the data and its archiving, the information (original data records) is available centrally in the database. In addition, the data is automatically prepared in the central system (e.g., in the form of aggregations). The central archiving of the data and its preparation allows the creation of flexible analyses over any areas and time periods without additional preparatory work. Employees are enabled to create their own analyses flexibly, based on historical data.

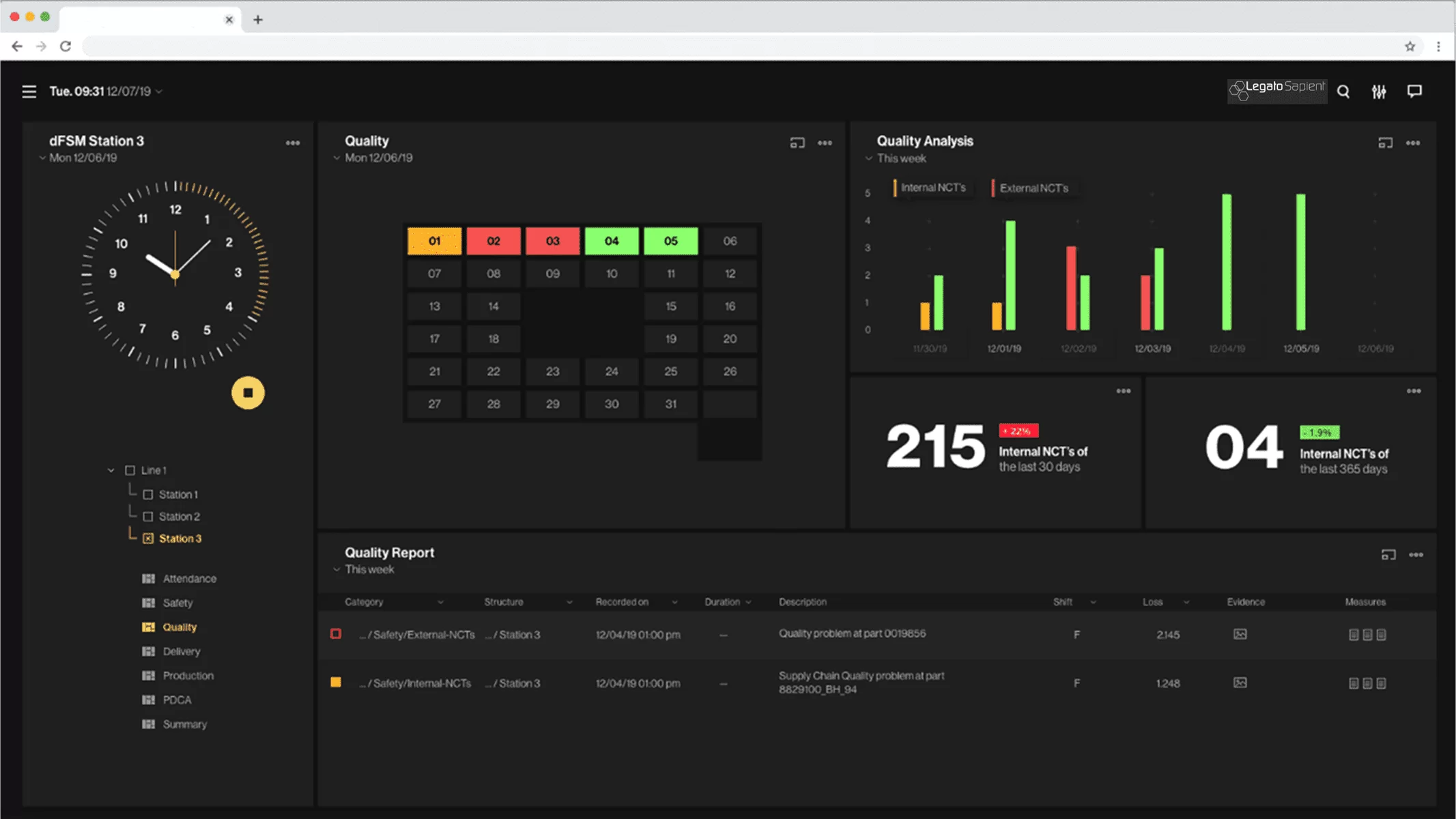

Deviations can be identified directly and dealt with in a targeted manner by observing progressions and trends. All evaluations and visualizations are based on the same original data records (including automatic aggregations etc.), which means that there are no discrepancies between original data and calculated data. A drill-down to the detail (from the executive dashboard to machine level) is therefore easily possible!

3. Employee motivation

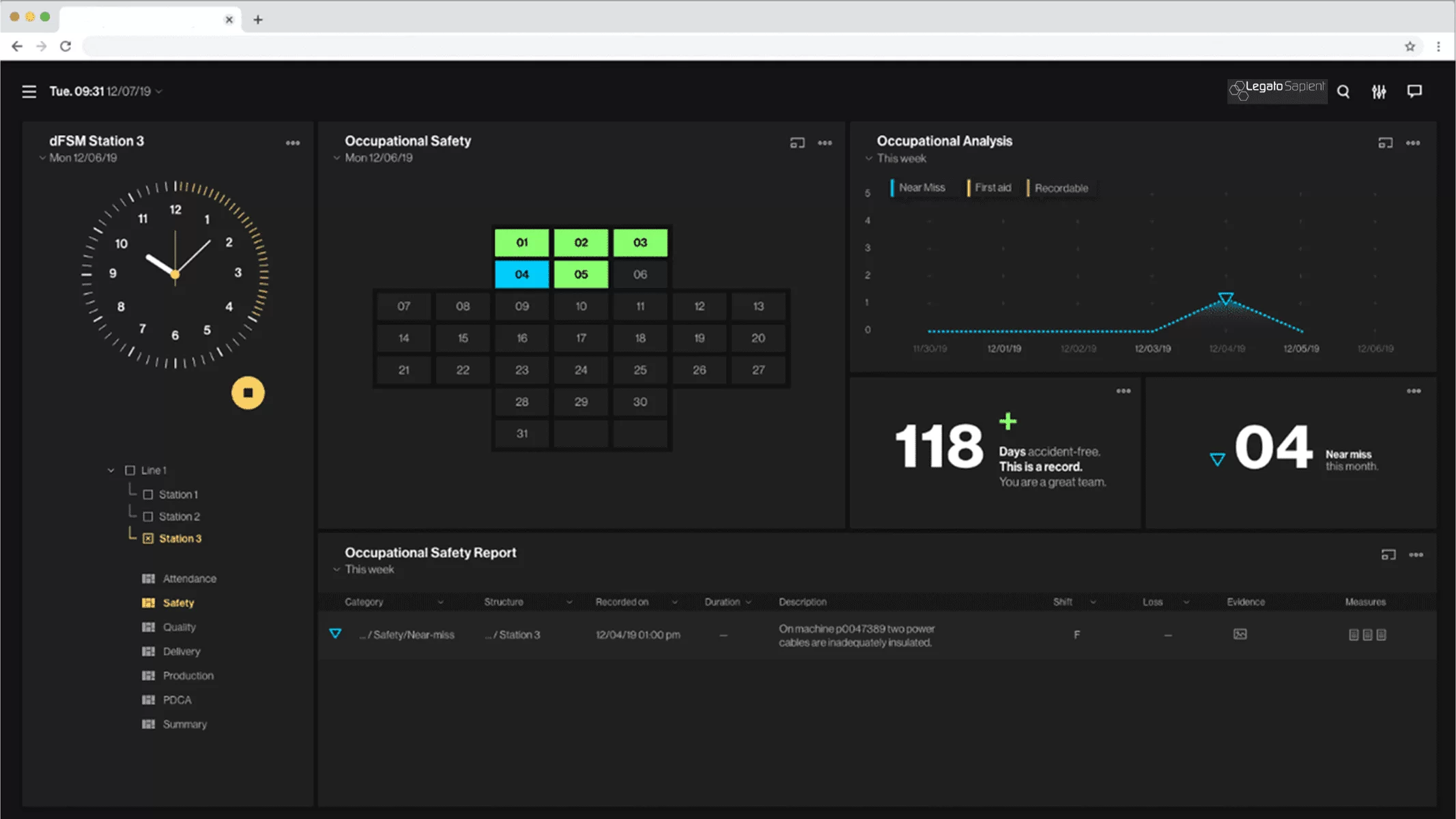

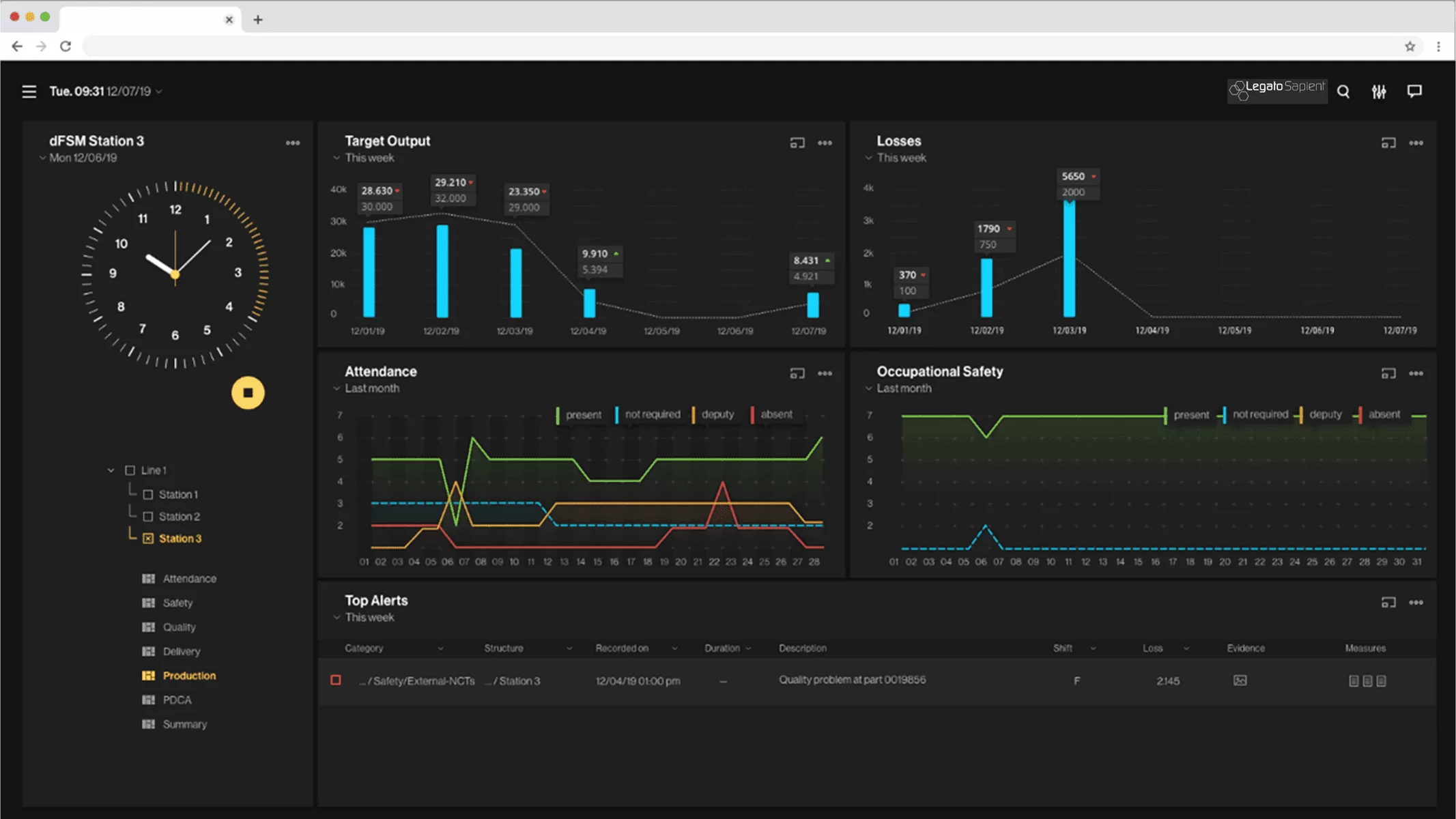

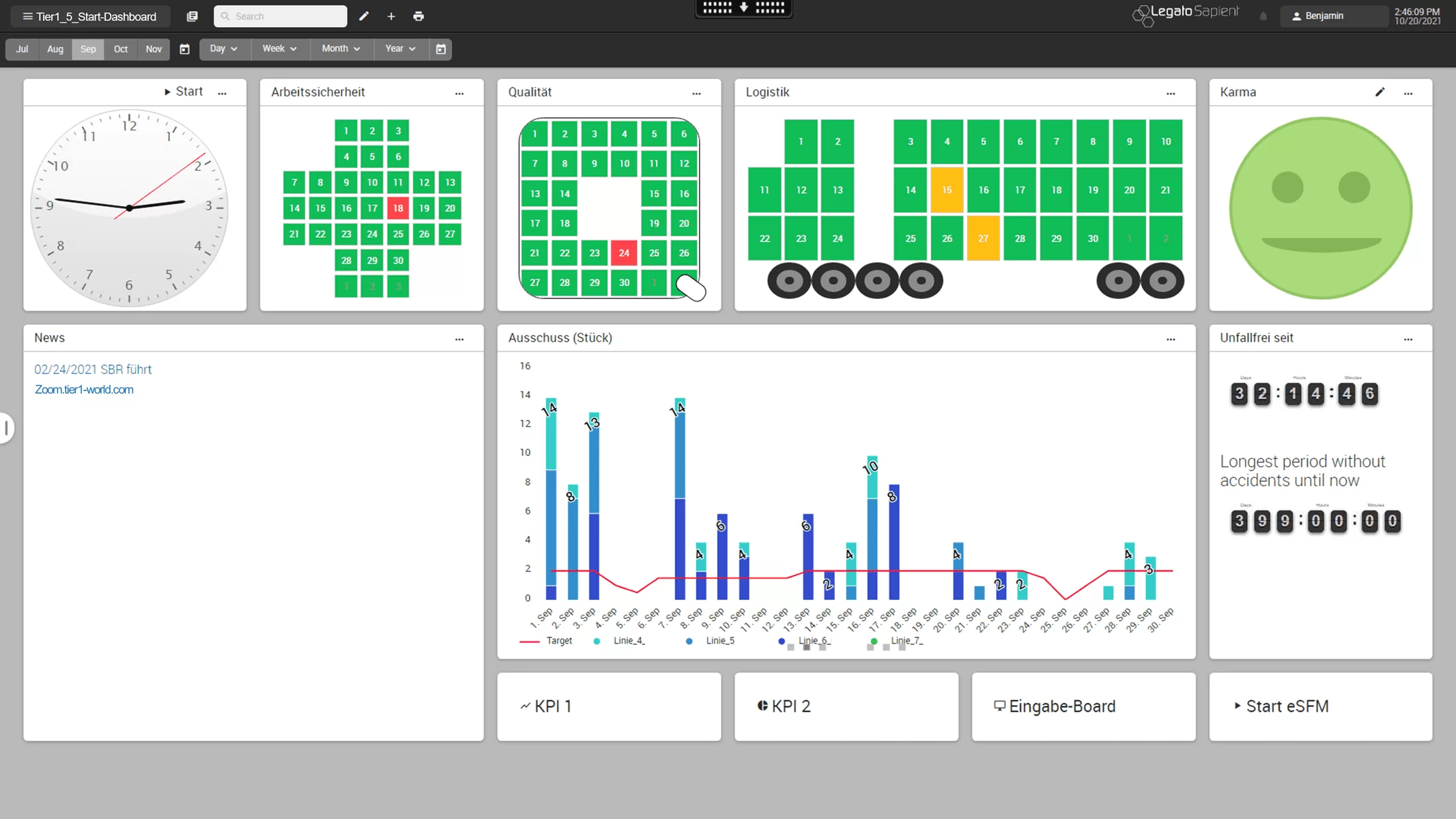

In the classic morning briefing, mostly rational topics play a role; the topic of “employee motivation” rarely finds a place in such a meeting. The archiving of data (e.g., accidents at work or number of units achieved) and its observation in the course of time additionally allows a visualization of information that has an impact on employee motivation – in this way, “successes” that have an impact on employee motivation can be visualized in the digital morning briefing. For example, in the area of occupational safety, the topic “Accident-free since…” can be visualized.

The productivity or performance of the previous shift could be underlined in the form of “smileys”, for example. If the planned number of pieces was achieved, a smiling “smiley” appears and turns green. Other scenarios are of course conceivable.

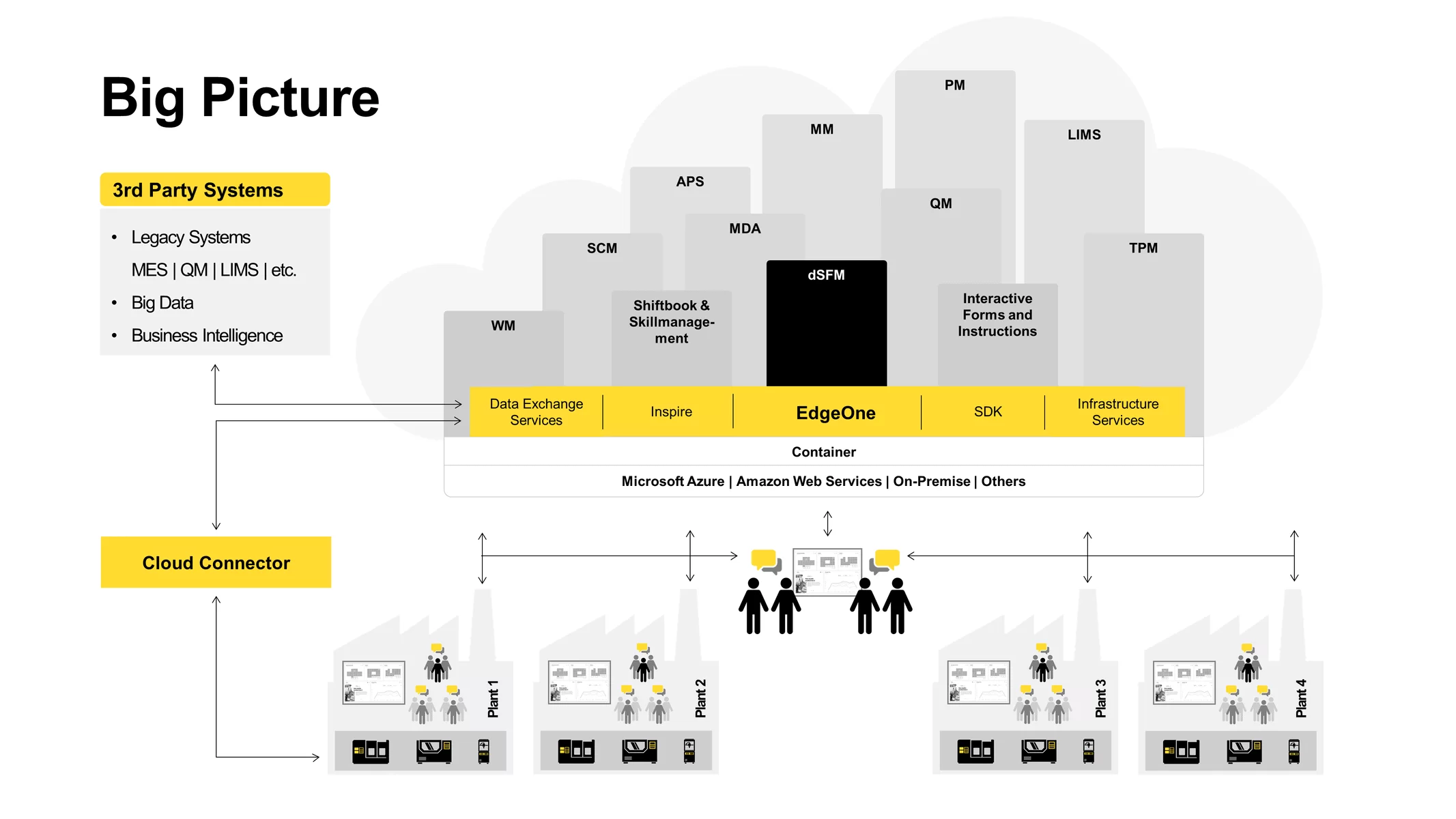

4. Visualizing data from different systems in one interface

In certain situations, it is necessary to analyze the process or a specific problem in more detail. For this purpose, additional information, apart from the data from the morning briefing, is necessary. Previously, such information was not available on an ad-hoc basis; rather, the employee had to “gather” it in additional systems/files. In the age of Industry 4.0, this workflow should be simplified to the extent that all relevant information is available directly in one view. For shopfloor management, this means integrating data from third-party systems (e.g., quality and logistics systems) in the central system.

Only in this way can data from different systems be visualized in one view or dashboard. However, the fewer systems need to be considered in the data analysis, the easier it is for the user (i.e., no, or only minimal disruption!).

5. Communicating efficiently – Shopfloor management as a dialog platform

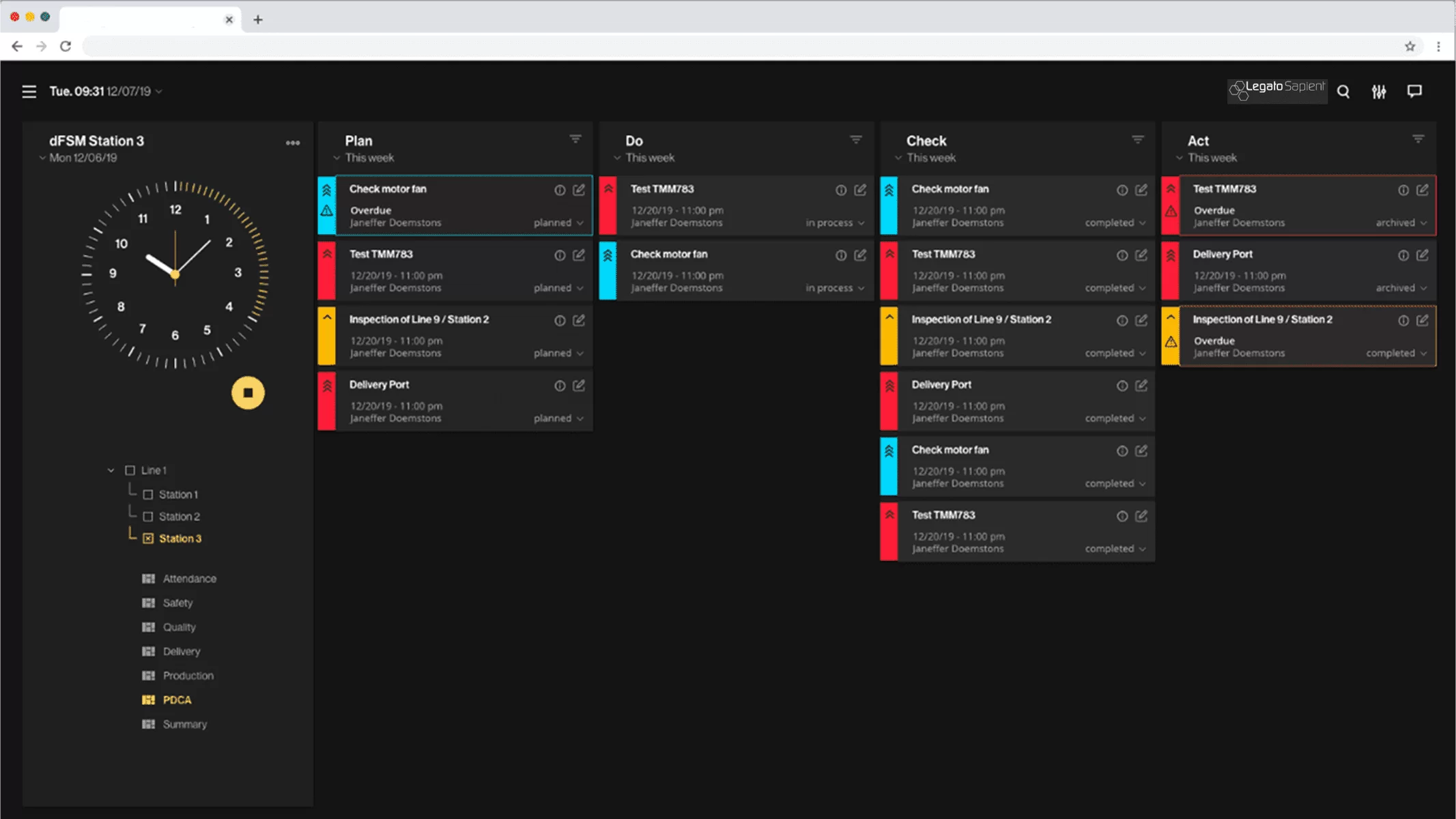

In addition to the contents of a morning briefing presented so far, the CIP (Continuous Improvement Process) or the resulting process improvement naturally represents one of the core elements. In the classic morning briefing, measures that lead to a process improvement are defined and listed on the pinboard digitally, including responsibility and planning dates – the measure or its status is only tracked manually.

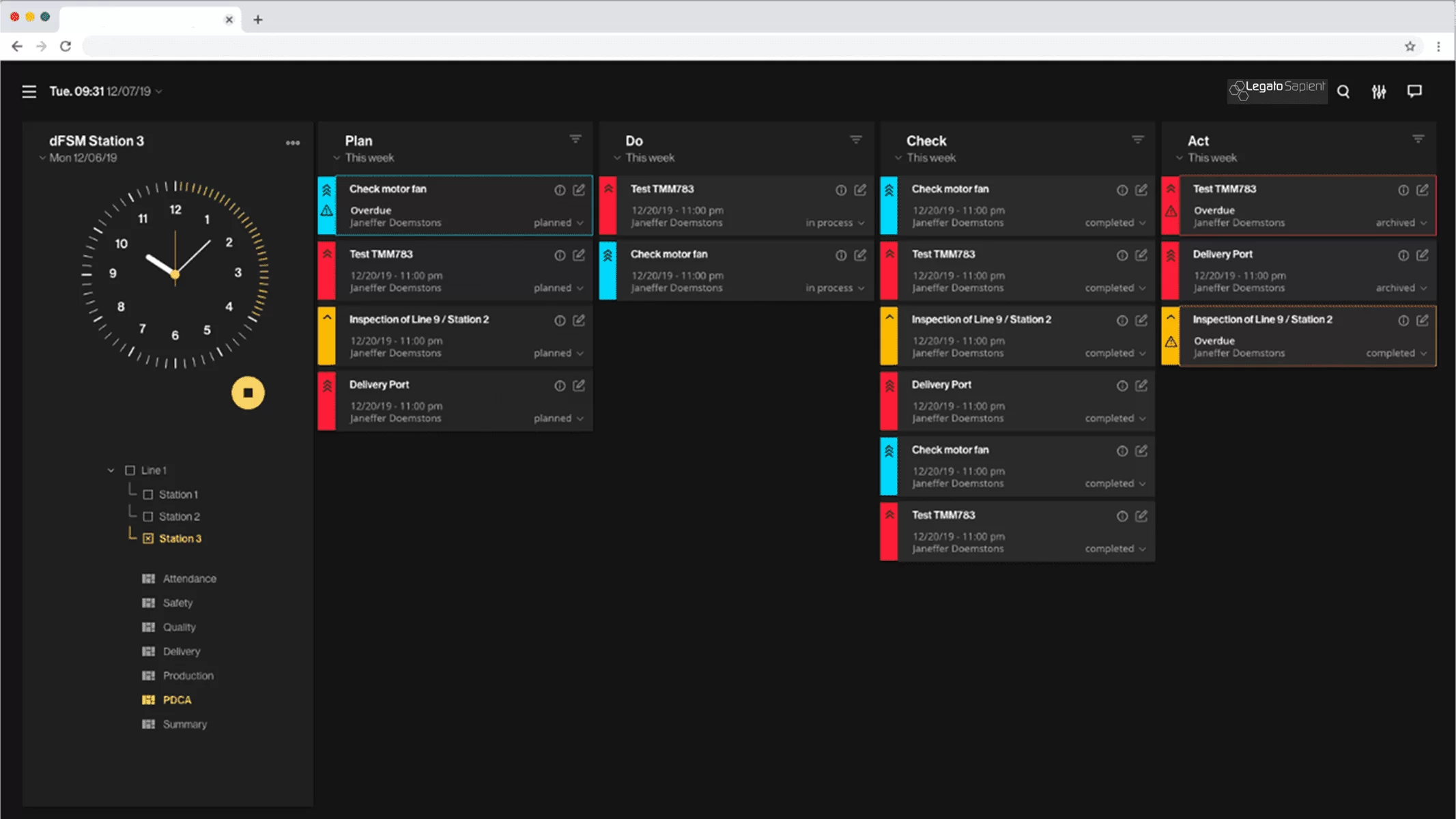

In the context of the digital morning briefing, the measures are created and archived in the central system – if the status etc. changes, the measure is automatically updated (digital measure management). Nevertheless, the known process remains the same: In the context of CIP, measures are defined to permanently eliminate regularly occurring problems (e.g., quality, plant malfunction, etc.). The PDCA cycle or Deming circle defines four phases that are passed through within the improvement process:

- A measure is defined (P – Plan)

- Then the measure is tested (D – Do)

- The result of the measure is carefully checked (C – Check)

- Introduction of the measure on a broad front (A – Act)

Tracking of the measures as well as their evaluation based on the four phases is thus possible at the push of a button.

If problems or measures arise that cannot be solved directly, additional help from experts is required. An integration of internal communication media, such as Slack or Teams, allows knowledge carriers to be called in temporarily without having to be personally present on site.

Digitizing the morning briefing creates an interactive, paperless production floor system for all production-related topics, from machine to employee – as part of an MES.

For the actual system operation, the MES should already include functions for IT systems, monitoring, and alarming in the basic configuration, which only need to be adapted slightly per application.

Click-Demo: Digital Shopfloor Management

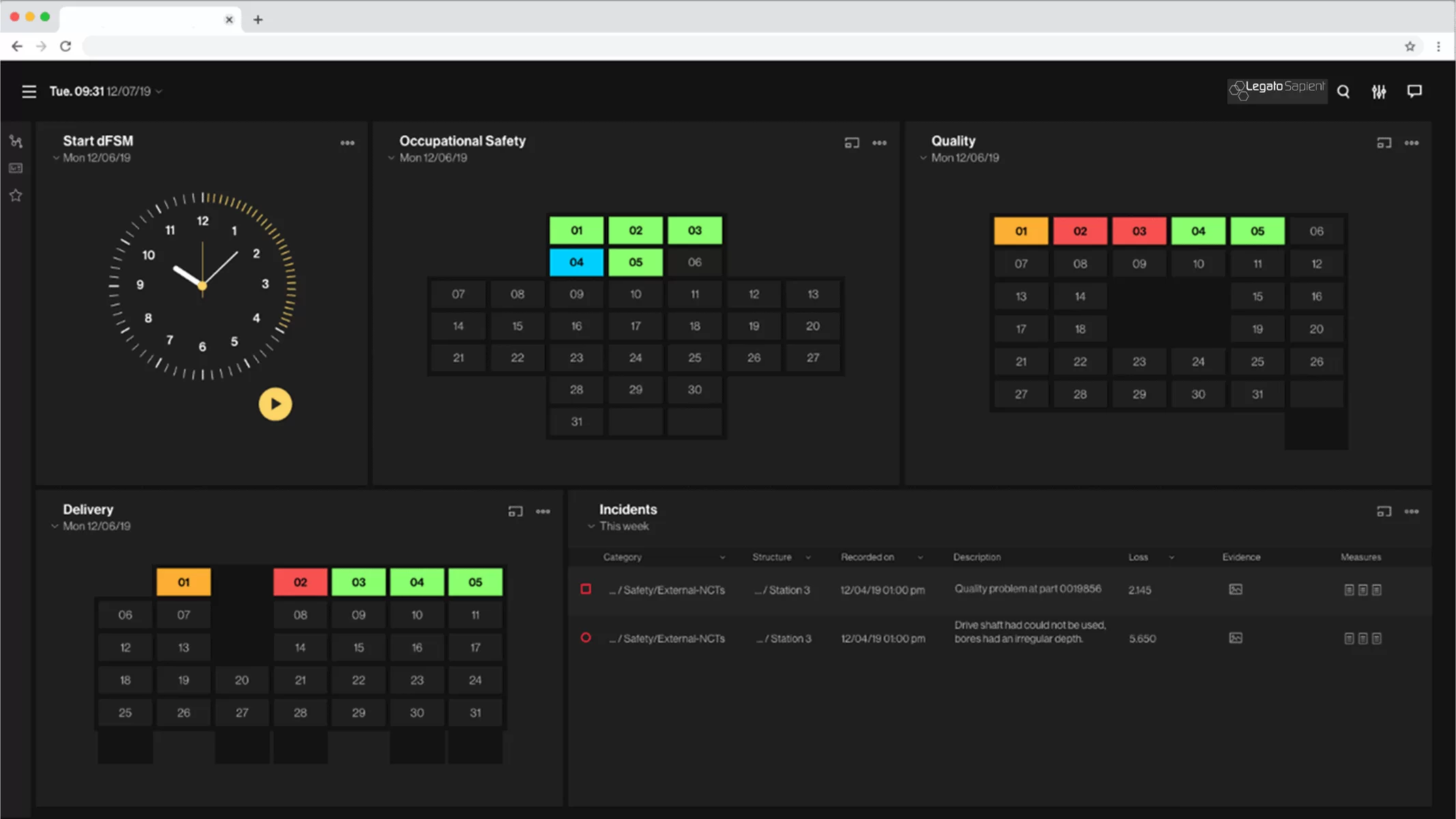

Start screen of the digital shopfloor board. 20-minute morning briefing is started. Safety, quality, and logistics are in focus.

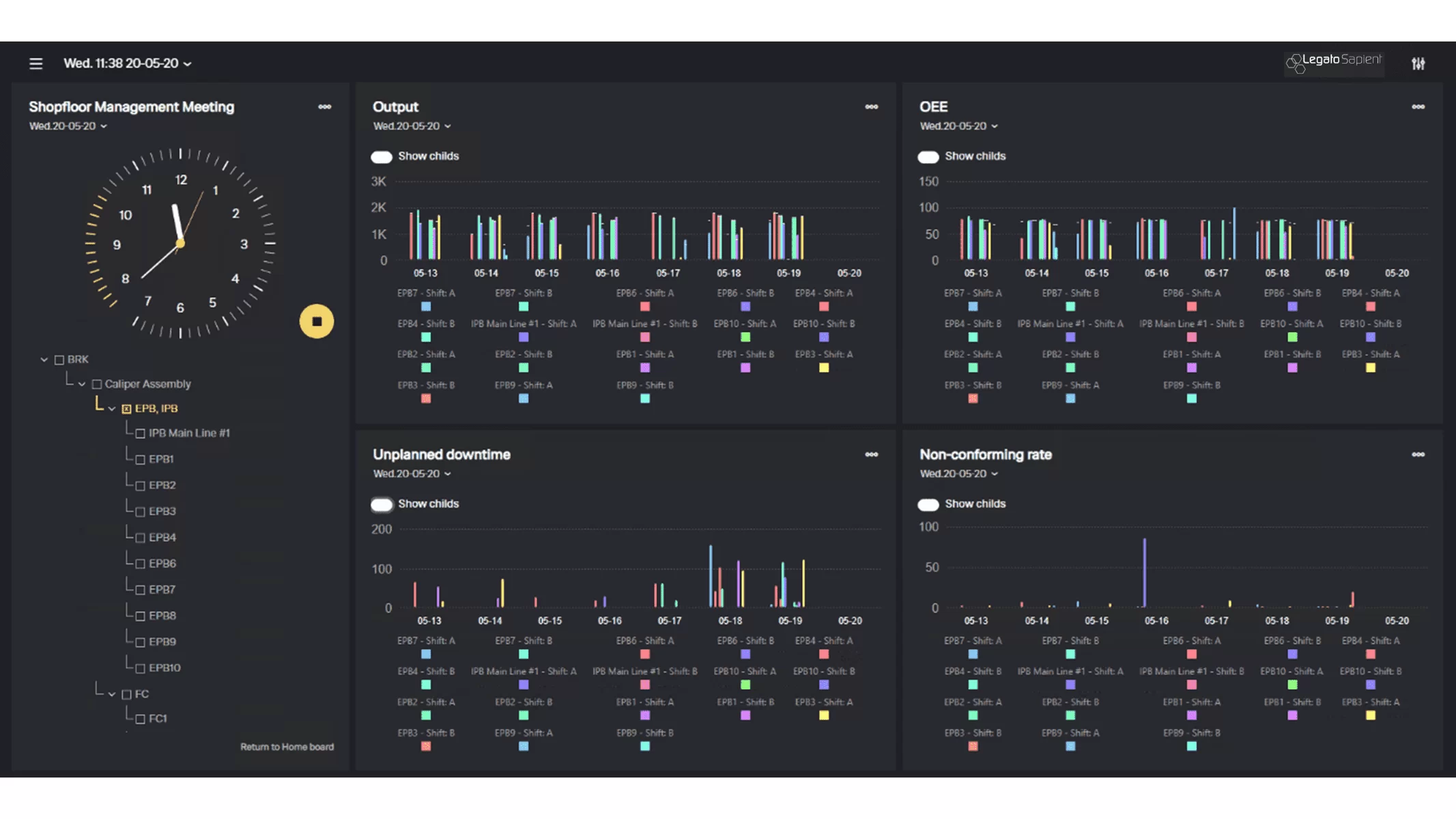

Predefined process with fixed number of participants or roles. One meeting per area / team is held per shift or day. Information is aggregated from the bottom up: Incidents (e.g., delays, accidents) or production figures (piece counters, KPIs) are recorded at the bottom on the store floor level. The aggregation of these values is then available at a higher level. For announcements and general information, the news boardlet is used, where the information flow takes place from top to bottom.

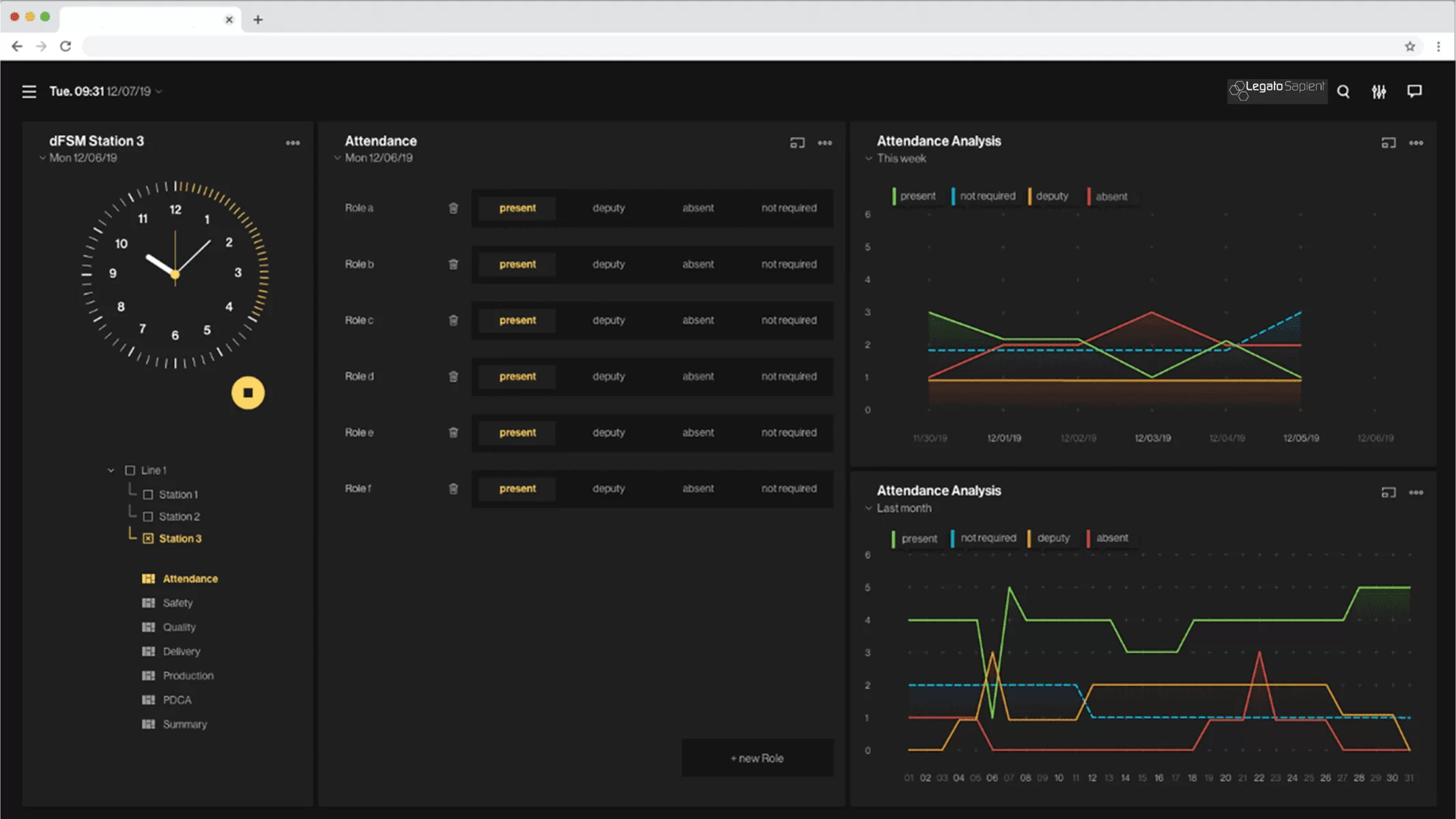

Shopfloor workers attendance

For each node or area where a shopfloor meeting is held, the participants or roles are initially defined. For these roles, the attendance per meeting is entered and can be evaluated in different views.

Occupational Safety

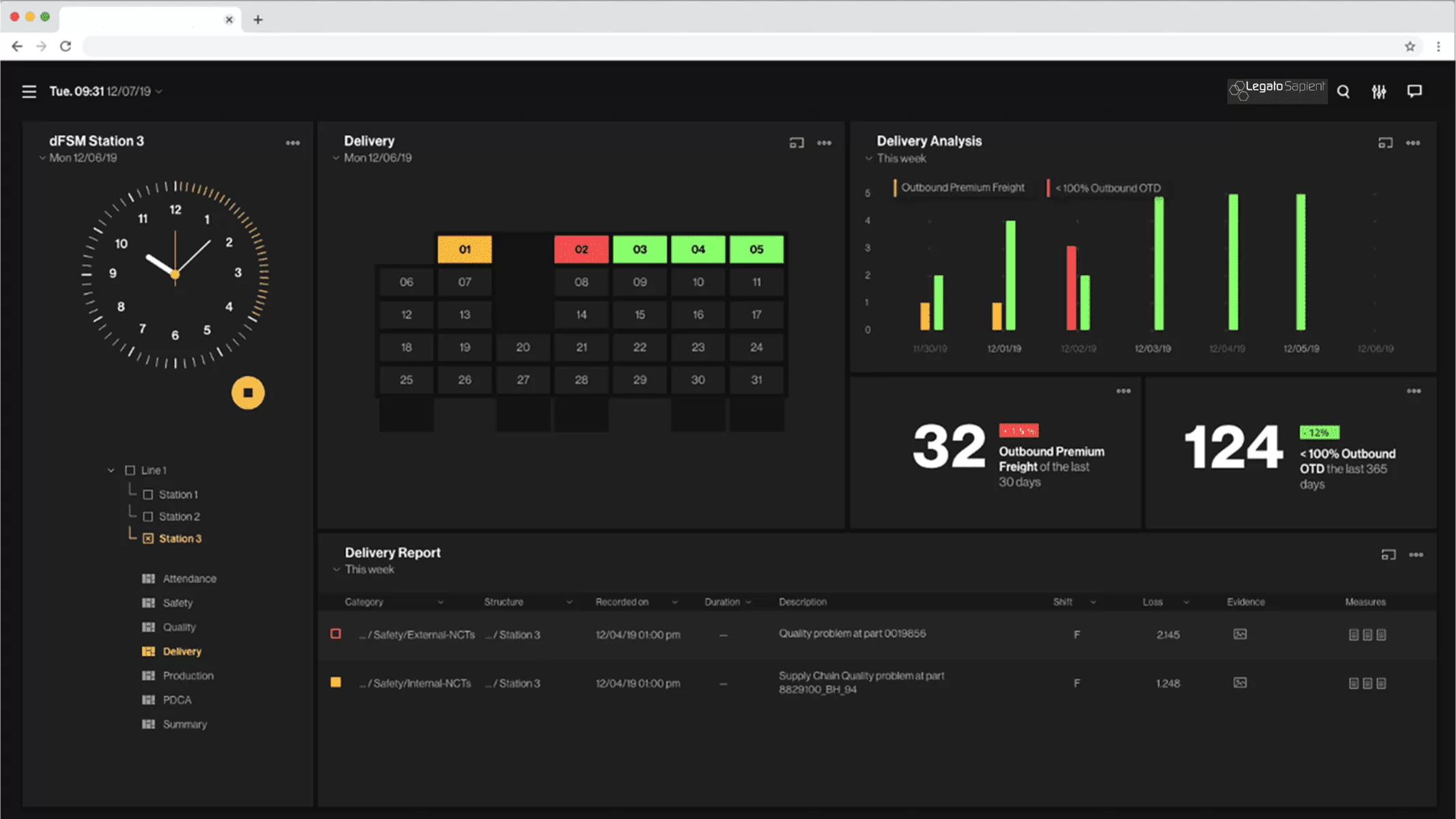

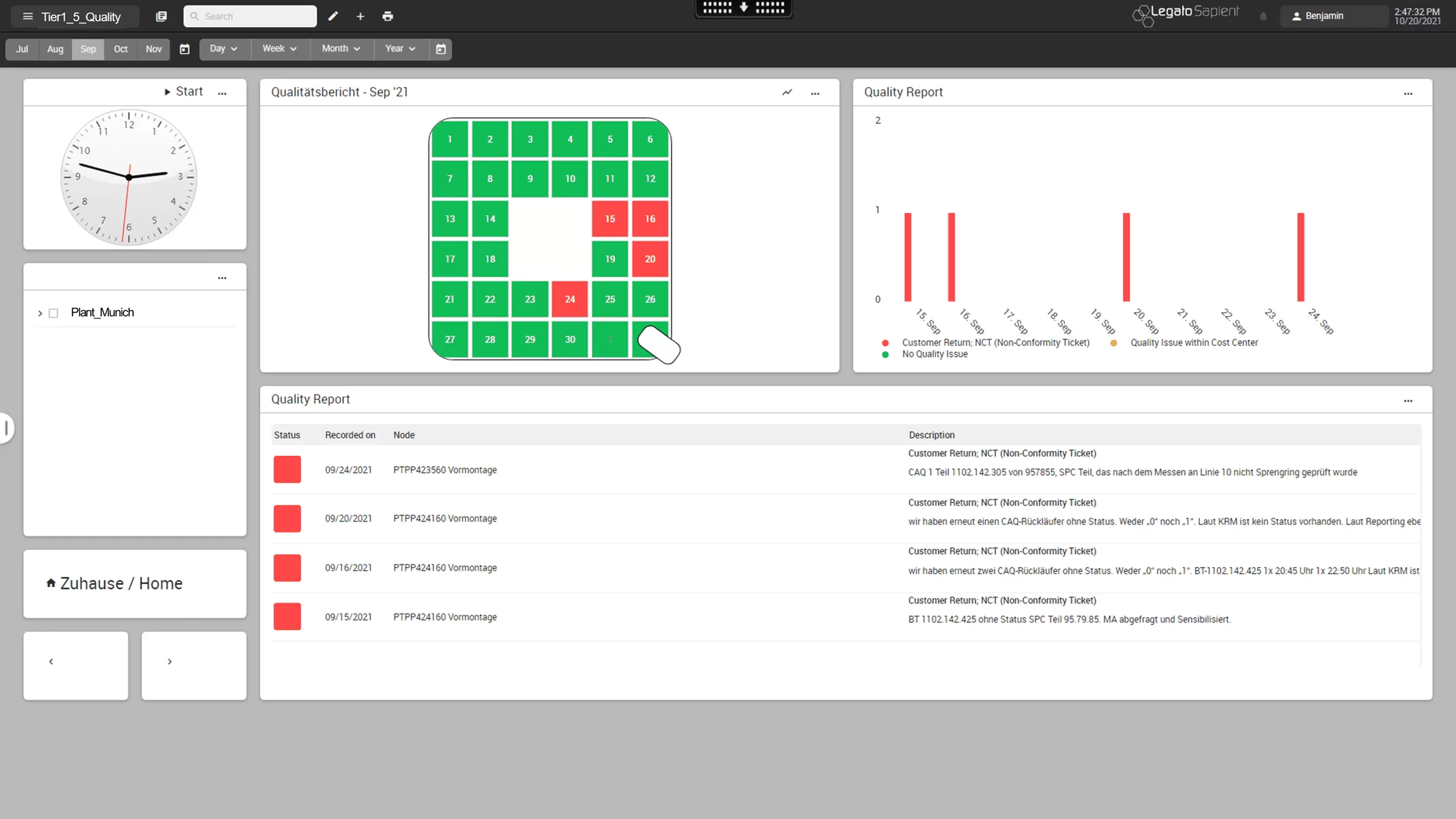

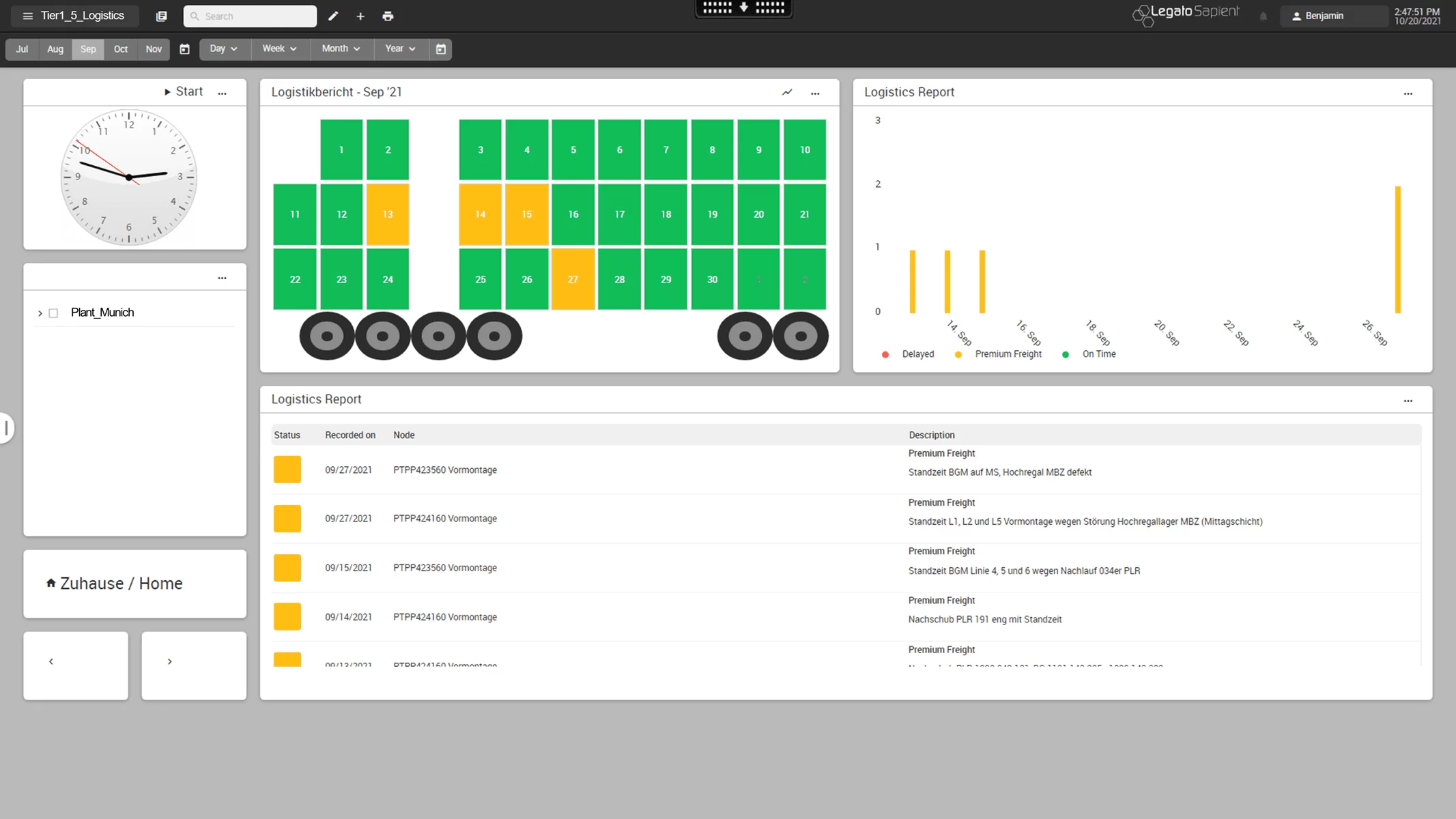

The three calendars; Safety, Quality, Logistics are used to record incidents. The option to provide customer-specific additional calendars can be guaranteed. An overview of the existing incidents filtered by area and incident type can be seen at the bottom of the dashboard. Selecting an incident in the list opens a window with a detailed view of the incident, in which it can be edited.

Quality

Logistics

General production KPIs

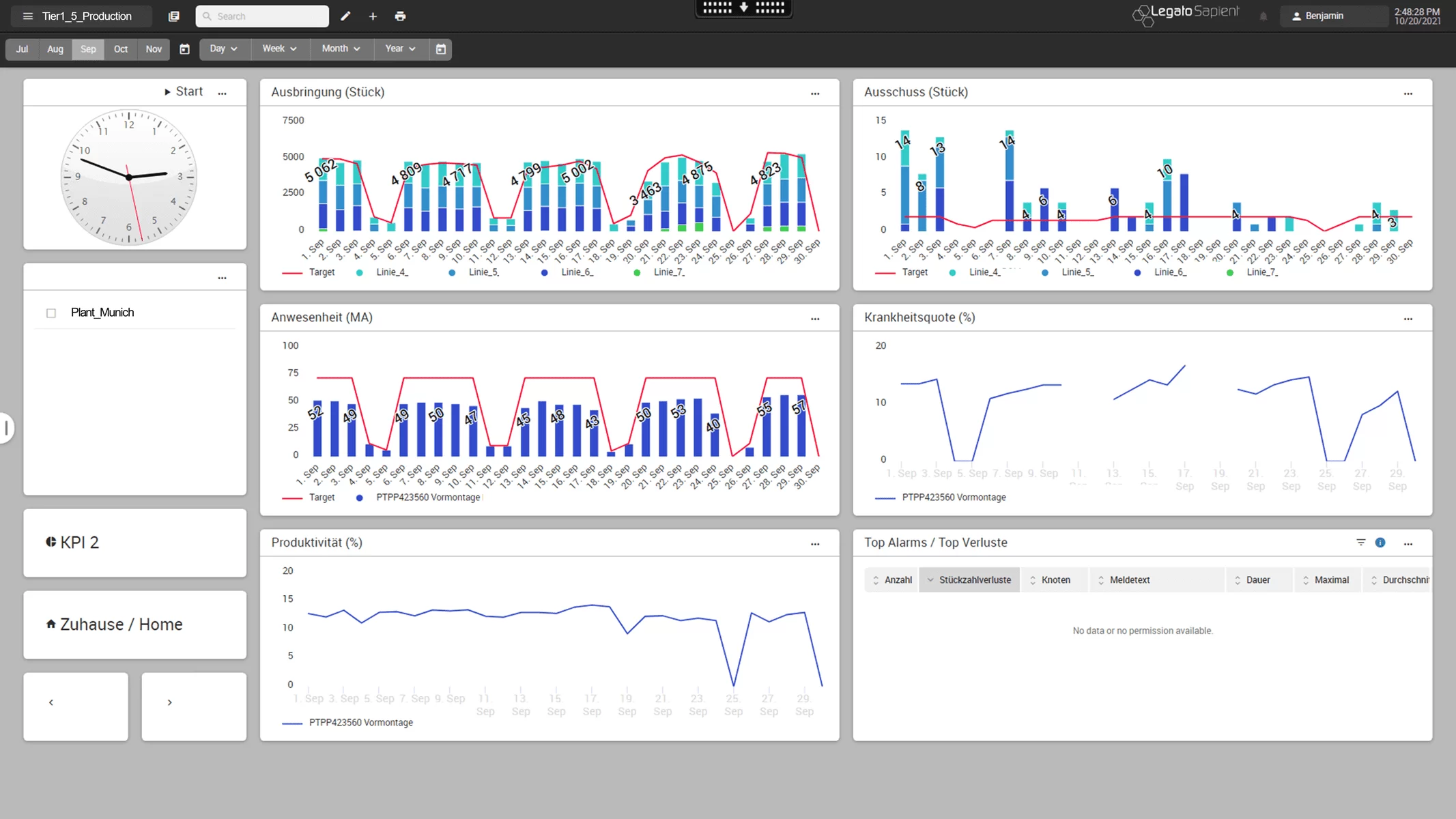

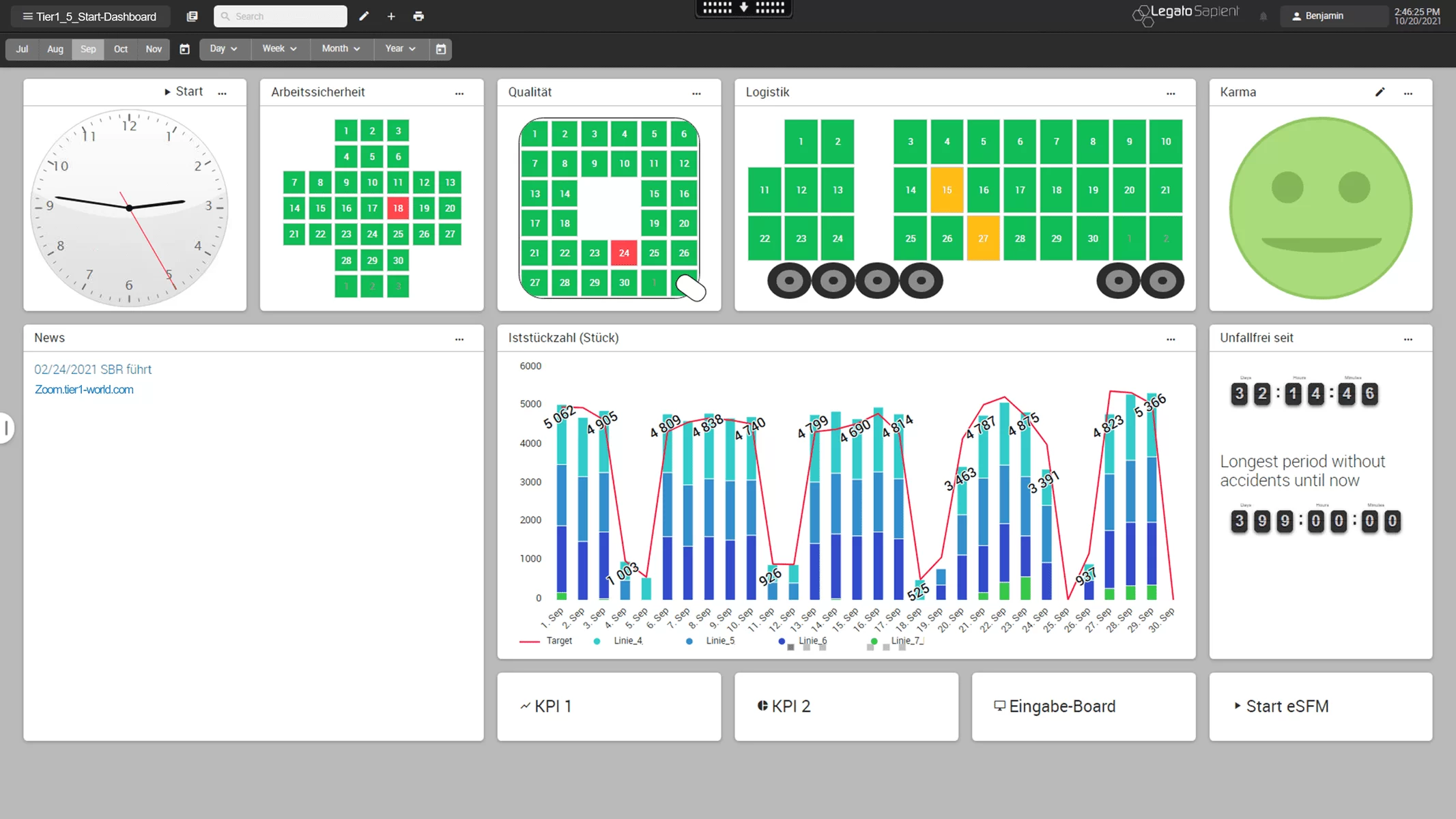

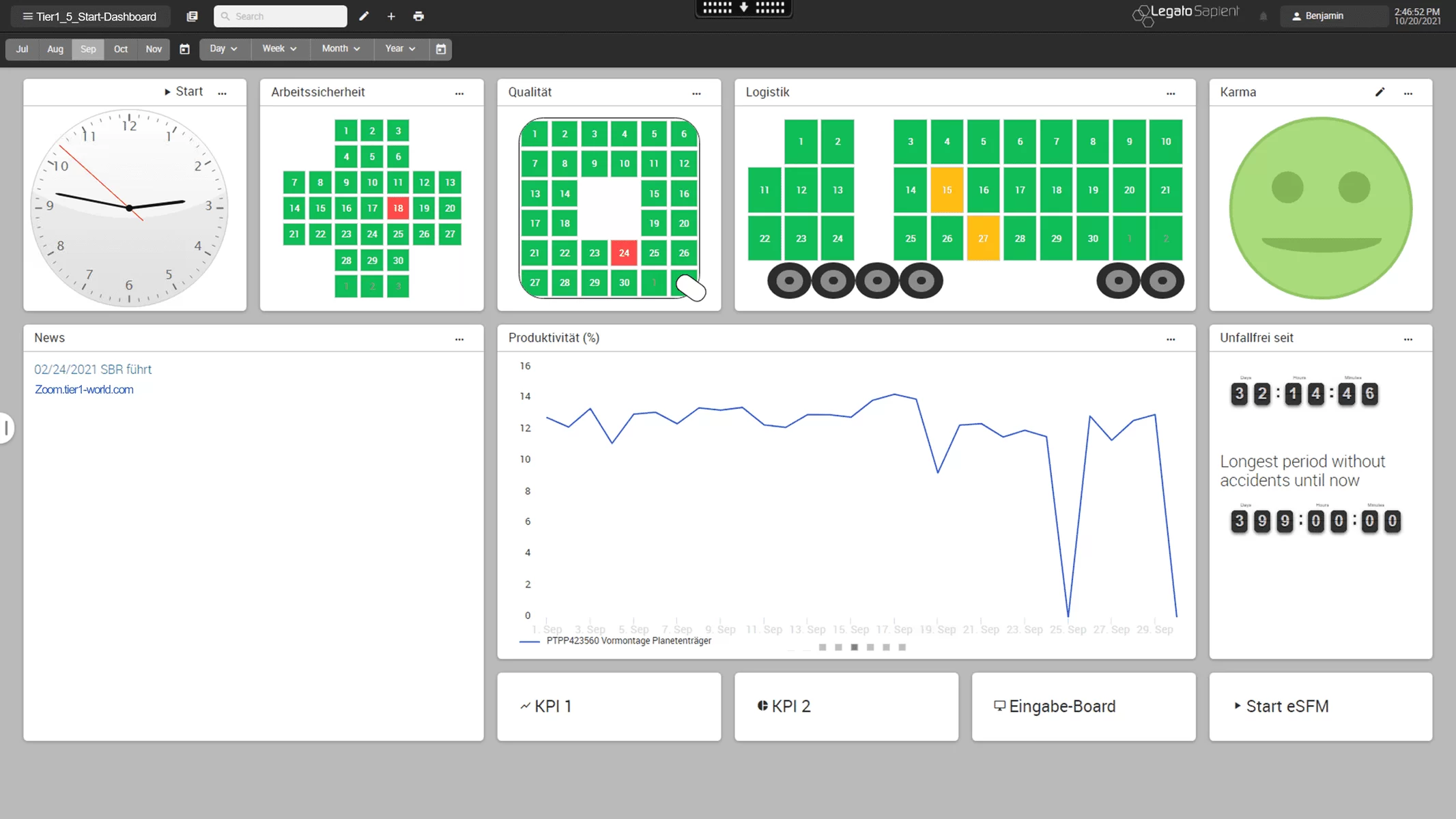

Drill down into the areas, lines, shifts, … online data from the MES system and the machines.

Viewing all relevant data from the machine data collection, prepared in the corresponding shopfloor boards, is part of the shopfloor management meeting.

Measures management

Measures are generated, for example, as a result of an incident (“Worker slipped” -> leads to measure “Clean floor”).

Task management enhancements: email notification, link to checklists, subtasks, assignment to user groups,

Digital Shopfloor Management: Example with focus on online machine, process, quality, and logistics data

The shopfloor management board provides direct access to necessary data of all types and origins. You have several options for data import:

- Already available in the system through ‘Machine Data Entry’.

- Manual input in the Interval Count Boardlet

- Connection via dedicated interface to additional system (e.g., SAP, legacy MES)

- File-based import via data that is regularly updated and read-in

Scrap:

Actual number of pieces:

Productivity:

For example, when quality is discussed, customer returns, quality issues, etc. are provided in a report. Furthermore, individual customer retractions from the CAQ system are further explained; all with drill down functionality for more detailed information.

If, for example, logistics is discussed, the delays, expensive premium deliveries, etc. are made available in a report. Furthermore, individual logistics problems (malfunction in the high-bay warehouse, replenishment too late, …) are explained. All with drill down functionality for more detailed information.

FAQ: Important questions about Digital Shopfloor Management

Here you will find answers to frequently asked questions about digital store floor management:

What is digital shopfloor management?

In manufacturing, the “shopfloor” is the workshop or factory floor. It is the place where production is carried out and where value creation happens. Shopfloor management therefore means that management takes place directly on the shop floor, i.e., the production and value creation processes are controlled by the active presence of managers on site.

Why is digital shopfloor management important?

On the one hand, digital shopfloor management is suitable for streamlining processes and minimizing production errors. You achieve noticeably more transparency based on machine data collection and evaluation. Digital shopfloor systems enable relevant analyses in one place and in real time.

What is a Shopfloor Meeting?

A Shopfloor Meeting is an effective production management tool. It usually has a regular agenda, takes place daily and lasts about 15 minutes. Shopfloor meetings are a dialog between production managers and employees and help to openly address process problems, get to the root of them and quickly eliminate them.